A Complete Guide to HAZOP, HIRA & QRA for Industries in Jeedimetla, Patancheru and Sangareddy

Fire Safety & Emergency Preparedness Requirements for Industries in Visakhapatnam Port and SEZ Areas

December 6, 2025

Fire Safety and Emergency Preparedness Requirements for Industries in Visakhapatnam Port and SEZ Areas

December 9, 2025Industrial zones like Jeedimetla, Patancheru and Sangareddy are home to chemical plants, pharmaceutical facilities, fabrication units and large-scale manufacturing operations. These industries face real operational risks whether it’s toxic chemical exposure, high-pressure systems, combustible dust, flammable gases, heavy machinery or confined spaces. With increasing regulatory pressure and growing awareness around employee safety, risk assessments are no longer optional. They are the backbone of compliance, prevention and long-term operational stability.

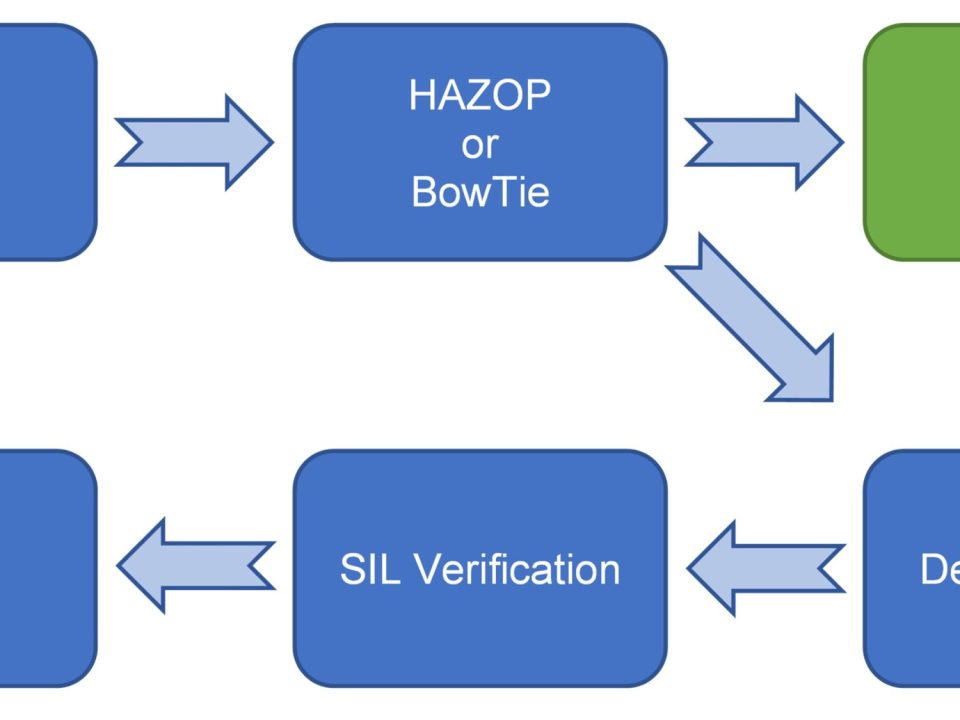

Three methodologies stand out in industrial safety and risk management: HAZOP, HIRA and QRA. Each one serves a different purpose, works at a different depth and helps industries build safer systems and workplaces.

This guide breaks down what they mean, why they matter and how companies across Telangana’s industrial belt can apply them strategically.

Why Industrial Safety Risk Assessments Matter

Accidents don’t just damage equipment. They stop production, cause injuries, destroy trust and hit profitability. In regions with dense industrial clusters like Jeedimetla and Patancheru, one incident can affect nearby communities, water sources and shared infrastructure.

Strong risk-based systems help with:

- Preventing workplace accidents

- Reducing operational downtime

- Meeting statutory compliance

- Avoiding environmental penalties

- Training employees on correct procedures

- Strengthening operational discipline

Risk assessment is not paperwork. It’s a practical decision-making tool that protects both the plant and the people who run it.

Understanding the Three Major Safety Assessment Methods

Industries often confuse HAZOP, HIRA and QRA as interchangeable. They are connected, but each one serves a different layer of risk identification and control.

Let’s break them down.

HAZOP (Hazard and Operability Study)

A Hazard and Operability Study is a structured method used to identify process deviations and their potential consequences. It is widely used in chemical processing units, pipeline systems and pharmaceutical formulation plants.

HAZOP focuses on “what can go wrong” in a system based on design intent. Instead of relying on assumptions, it evaluates every node of a process and challenges its operational behavior.

You can explore more about it here: Hazop Study

Examples:

- “Too much pressure in a reactor vessel”

- “Loss of flow in a cooling water line”

- “Reverse flow in a transfer pump”

Where HAZOP Helps:

- Commissioning of new plants

- Modifications or expansions (MOC)

- Preventing major failures in pipelines, reactors and storage tanks

Simply put, HAZOP prevents design-related failures before they turn into real-world disasters.

HIRA (Hazard Identification and Risk Assessment)

HIRA takes a broader approach. It evaluates risks associated with workplace activities, equipment and human behavior rather than deep technical design failures.

This method identifies hazards, assigns a risk rating and determines whether controls are adequate or need improvement.

Examples of HIRA Areas:

- Work at height

- Electrical maintenance

- Forklift movement

- Chemical handling

- Hot work in fabrication industries

- Warehouse stacking and loading

HIRA is essential for OSHA compliance and is a core part of routine plant safety planning.

QRA (Quantitative Risk Assessment)

Where HIRA and HAZOP identify hazards qualitatively, QRA puts numbers into the picture. It calculates the probability and magnitude of an incident using statistical modeling, historical data and simulation tools.

Industries in Sangareddy and Patancheru dealing with LPG terminals, bulk solvent storage, boilers or explosive environments require QRA because failure is not just internal it affects surrounding communities.

QRA Typically Evaluates:

- Fire and explosion risks

- Toxic gas dispersion

- Domino effects

- Individual and societal risk impacts

QRA is especially relevant in areas where industrial zones border residential or environmentally sensitive areas.

When Should These Methods Be Used?

Many companies assume these studies are required only during new plant construction, but that’s shortsighted. Risk evolves with operations.

Ideal stages to apply these methods include:

| Stage | HAZOP | HIRA | QRA |

|---|---|---|---|

| New plant design | ✓ | ✓ | ✓ |

| Process modification | ✓ | ✓ | ✓ |

| Routine safety planning | ✓ | ||

| Post-incident analysis | ✓ | ✓ | ✓ |

| Before commissioning | ✓ | ✓ | ✓ |

Think of them as complementary layers rather than alternatives.

Compliance and Legal Requirements

Manufacturing and chemical plants in Telangana are governed by regulations including:

- Factory Act

- SMPV Rules

- Environment Protection Act

- Explosives Act

- OSHA guidelines

- ISO 45001

Most insurance and government audits today require documented risk assessment proof. Companies that take safety seriously don’t wait for compliance officers to force change.

Tools That Strengthen Risk Assessment

Some additional assessments support HAZOP, HIRA and QRA work.

Safety Audit

A well-structured Safety Audit helps verify whether existing controls align with real-world practices. Most companies assume they are compliant until an audit proves otherwise.

Fire Audit

A Fire Audit is essential for industries handling flammable liquids, dust or thermal equipment. Fire preparedness is not just installing extinguishers. It involves system testing, evacuation drills, alarm system validation and equipment readiness.

Process Safety Management

For larger industrial operations, Process Safety Management brings structure to chemical and process-based decisions. It ensures changes, shutdowns, maintenance and high-energy equipment are managed safely.

Why Industries in Jeedimetla, Patancheru and Sangareddy Need Risk Studies Now

These regions are developing fast. The density of chemical and pharma industries means one mistake could trigger a chain reaction. Land values are rising, local authorities are tightening compliance and global companies now demand proof of risk management from their suppliers.

Ignoring risk today is not just irresponsible. It’s expensive.

Building a Culture of Prevention

Risk assessment systems only work if employees understand why they matter. Many companies create documents, tick boxes and move on. That mindset is a major reason accidents repeat themselves.

A better approach includes:

- Clear SOPs

- Regular safety drills

- Training based on real hazards, not theory

- Cross-functional participation in audits

- Accountability built into operations

Safety grows when it becomes a natural part of daily work.

Choosins the expertise to run deep risk analysis. Working with an experienced Safety Consultant helps bring structure, experience from other industries and unbiased insights.

A good consultant doesn’t just hand over reports. They work with the team, train them, help fix gaps and support long-term improvements.

Final Thoughts

HAZOP, HIRA and QRA are not academic exercises. They are practical tools that prevent accidents, strengthen compliance and protect people and investments. For industries in Jeedimetla, Patancheru and Sangareddy, applying these assessments systematically isn’t just smart. It’s necessary if the aim is long-term operational stability and responsible industrial growth.