A Complete Guide to HAZOP, HIRA & QRA for Industries in Jeedimetla, Patancheru & Sangareddy

Top Industrial Safety Challenges in Hyderabad & How Companies Can Overcome Them in 2025

December 4, 2025

Fire Safety & Emergency Preparedness Requirements for Industries in Visakhapatnam Port and SEZ Areas

December 6, 2025Industrial hubs like Jeedimetla, Patancheru and Sangareddy are growing quickly across pharmaceuticals, chemicals, engineering and heavy manufacturing. As operations scale, so do the risks linked with hazardous materials, complex machinery and round-the-clock production. This is where a structured approach to risk management becomes non-negotiable. The Safety Master supports industries in these regions with advanced methodologies such as HAZOP, HIRA and QRA to strengthen safety performance, reduce uncertainty and ensure compliance. This guide explains how these three frameworks work, why they matter and how industries can use them to build a resilient and safe work culture.

Why Industrial Risk Management Matters in Telangana’s Fast-Growing Clusters

Companies across Jeedimetla, Patancheru and Sangareddy operate within strict regulatory environments and high-risk conditions. Process deviations, chemical leaks, fires, or equipment failures can trigger huge downtime, legal action and environmental damage. A single gap in planning can disrupt the entire supply chain. With rising demand and competitive pressure, industries cannot rely on reactive safety. They need predictive systems that uncover hidden risks before they escalate. HAZOP, HIRA and QRA are among the most effective frameworks for this purpose. Each one tackles risk from a different angle and together they create a strong safety foundation.

Understanding HAZOP: A Systematic Approach to Identifying Process Deviations

HAZOP, or Hazard and Operability Study, is one of the most widely used techniques in process industries. It focuses on identifying how deviations from the design intent can lead to operational issues or hazards. The Safety Master supports companies with expert facilitators who lead teams through structured discussions using guidewords like “more,” “less,” “reverse” and “other than.” These guidewords help uncover credible deviations in pressure, temperature, flow, reaction pathway and other critical parameters. A certified Hazop Study Consultant ensures the study remains systematic and unbiased. For industries in Jeedimetla, Patancheru and Sangareddy, where batch processes, reactors, distillation units and solvent handling are common, HAZOP plays an essential role in preventing process-related incidents.

Key Benefits of HAZOP for Local Industries

It identifies hazards linked to design or operational anomalies before commissioning. It improves team understanding of the process and equipment by encouraging cross-functional participation. It supports documentation that satisfies regulatory requirements and client audits. It guides engineering changes, plant upgrades and the development of safe operating procedures. Because HAZOP digs deep into design and operations, it is especially valuable in chemical, pharmaceutical and oil & gas units operating in Telangana’s industrial corridors.

HIRA: A Practical Method for Workplace Hazard Identification

HIRA stands for Hazard Identification and Risk Assessment. It looks at routine and non-routine tasks performed by employees and evaluates the risk levels associated with each. Unlike HAZOP, which is tied to process design, HIRA applies to day-to-day operations. It helps organizations classify risks based on severity, probability and existing controls. A strong HIRA program improves workforce awareness and promotes safe work practices across the plant floor. Industries in Jeedimetla, Patancheru and Sangareddy often deal with chemical storage, waste management, hot work, material handling and confined spaces. HIRA allows them to evaluate and reduce the risks linked with these activities.

Benefits of HIRA in Manufacturing and Processing Units

It helps in developing safe job procedures based on identified risks. It reduces workplace accidents by raising awareness among workers and supervisors. It supports compliance with statutory standards and audit requirements. It builds a proactive attitude toward safety at all organizational levels. By integrating HIRA into daily operations, companies can ensure that safety isn’t limited to engineering controls but becomes a consistent work habit.

QRA: Quantifying Risk for Better Decision-Making

Quantitative Risk Assessment (QRA) evaluates the probability and consequences of major accidents such as explosions, toxic releases and fires. It uses mathematical models, historical data and scenario analysis to understand the worst-case impact of hazardous events. QRA is essential for high-risk industries and is often mandated by regulators for installations dealing with toxic or flammable materials. The Safety Master uses advanced modelling software and experienced risk engineers to perform detailed consequence modelling. This helps industries understand individual risk, societal risk and potential exposure zones around the facility.

Why QRA Is Important for Industrial Zones like Patancheru and Sangareddy

These clusters house chemical units, solvent recovery plants, bulk drug manufacturers and engineering facilities. Any large-scale incident can affect nearby industries and residential areas. QRA provides decision-makers with numerical insights that support land-use planning, emergency preparedness and investment in safety improvements. It highlights gaps in isolation distances, venting systems, mitigation barriers and emergency response capabilities. By quantifying risk, companies gain clarity on where to allocate resources for the highest safety impact.

How HAZOP, HIRA and QRA Work Together

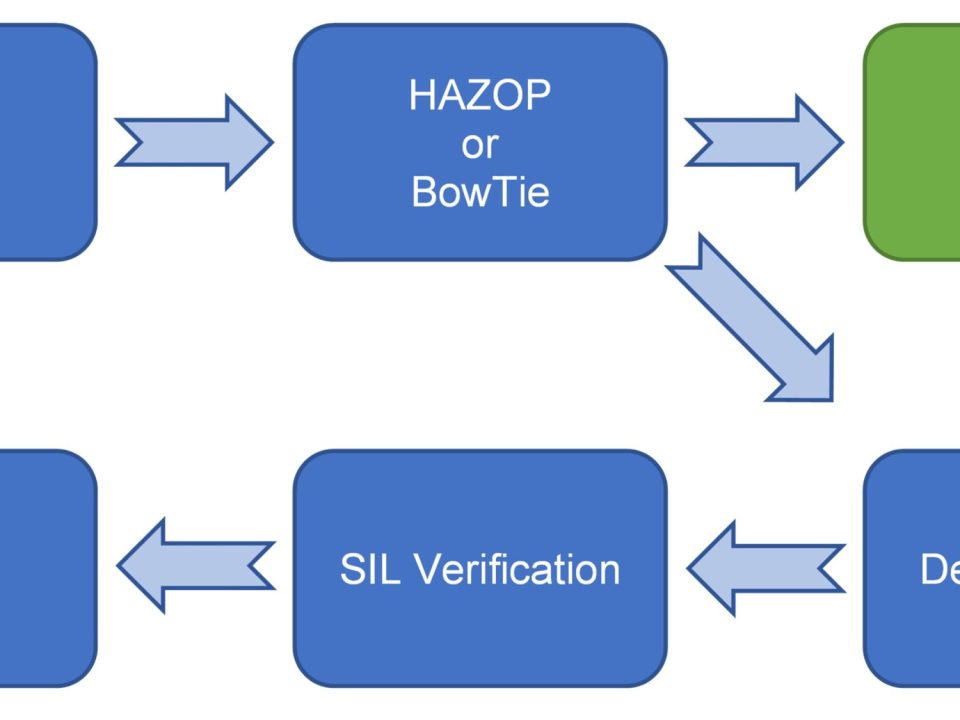

These three methodologies complement each other. HAZOP identifies deviations and hazards rooted in process design. HIRA covers workplace-level operational risks. QRA evaluates the potential impact of severe incidents. When implemented together, they form a holistic risk management strategy that supports engineering safety, operational discipline and emergency preparedness.

Combined Benefits for Industries in Jeedimetla, Patancheru and Sangareddy

Better decision-making through a mix of qualitative and quantitative assessments. Stronger compliance with Indian standards and global safety frameworks. Improved safety culture through participation from all departments. Lower downtime, reduced insurance claims and stronger customer confidence. The Safety Master helps organizations integrate these methodologies into a continuous improvement cycle. This ensures safety stays relevant even as technology, production or workforce requirements change.

The Role of Safety Audits and Fire Prevention in Strengthening Risk Management

Risk assessment frameworks are only effective when supported by regular audits. Assessments reveal what could go wrong, while audits verify whether the controls are working. A Safety Audit in India helps evaluate the effectiveness of existing systems, statutory compliance and overall preparedness. It highlights shortcomings that may not be visible during routine inspections. Fire hazards remain a major concern in industrial clusters with solvent storage, electrical equipment, packaging materials and high-temperature processes. A professional Fire Safety Audit helps identify ignition sources, gaps in suppression systems, evacuation readiness and emergency equipment reliability. These audits give industries a clear path to close safety gaps and strengthen protection across operations.

Building Competency Through Training and Workforce Development

Even the most advanced system fails if the workforce does not understand how to use it. Skill development is central to safety management and helps employees respond correctly during emergencies. The Safety Master supports industries with specialized Process Safety Management Training that covers risk assessment, process controls, human factors and incident investigation. Training creates awareness, builds accountability and ensures employees understand the consequences of unsafe acts or deviations. In high-risk industries, training is not optional. It is an investment that protects people, equipment and business continuity.

Why Businesses Trust The Safety Master

The Safety Master has been a trusted partner for industries across Telangana and India. The team brings deep knowledge of industrial processes, regulatory standards and risk management frameworks. Their approach is practical, detail-oriented and tailored for each facility. Whether a company is commissioning a new plant, expanding capacities or improving existing processes, The Safety Master helps create a safer work environment backed by proven methodologies and real industry experience. Their services combine technical accuracy with hands-on support, which is essential for industries dealing with complex hazards.

How to Implement HAZOP, HIRA and QRA in Your Facility

Industries looking to strengthen risk management should take a structured approach. The first step is identifying which assessment is most relevant based on your operations. Next, assemble a competent team with engineering, operations and maintenance backgrounds. Provide them access to updated P&IDs, SOPs, layout drawings, MSDS and emergency plans. Engage a qualified external expert for facilitation, as this ensures objectivity and technical precision. Once the studies are completed, convert findings into actionable recommendations. Assign ownership, define timelines and verify completion through audits. Creating a review cycle ensures safety remains dynamic and responsive to operational changes.

Final Thoughts

As industries in Jeedimetla, Patancheru and Sangareddy continue to grow, the need for strong risk management frameworks becomes more urgent. HAZOP, HIRA and QRA provide a structured approach to identifying, evaluating and mitigating hazards before they escalate. When combined with audits, training and a committed safety culture, they help organizations protect people, assets and the environment. The Safety Master continues to support companies with expertise that drives lasting safety improvements. For businesses seeking reliability and long-term value, these methodologies are not optional. They are essential tools for sustainable industrial growth.