An In-Depth Analysis of LOPA & SIL Study for the Process Industry in India: Ensuring Safety and Reliability

Uncovering Potential Hazards: The Role of Electrical Safety Audits in Improving Workplace Safety in Indian Manufacturing Industries

November 23, 2024

The Vital Importance of Regular Electrical Safety Audits in Indian Manufacturing Facilities

November 26, 2024In this article, we delve into the intricacies of LOPA (Layer of Protection Analysis) and SIL (Safety Integrity Level) study for the process industry in India. Safety and reliability are paramount in any industrial setting, and understanding the importance of these studies is crucial in minimizing risks and potential hazards. Join us as we explore the various components of LOPA and SIL, their methodologies, and how they ensure a safer and more reliable working environment. By the end of this article, you’ll gain a comprehensive insight into these studies, arming yourself with the knowledge to prioritize safety in your own industry.

Introduction

The safety and reliability of industrial processes are of paramount importance in ensuring the well-being of workers and the surrounding community. In the process industry, where complex systems and hazardous materials are involved, it is crucial to implement robust risk assessment methodologies to identify potential hazards and mitigate them effectively. One such methodology that has gained significant recognition in recent years is Layers of Protection Analysis (LOPA) combined with Safety Integrity Level (SIL) Study. In this comprehensive article, we delve deep into the world of LOPA & SIL Study for the process industry in India. We will explore its key components, methodologies, and its integration into process safety management. Additionally, we will analyze case studies that showcase successful implementations of LOPA & SIL Study. By the end of this article, you can expect to have a thorough understanding of how LOPA & SIL Study contributes to ensuring safety and reliability in the process industry

Understanding LOPA & SIL Study

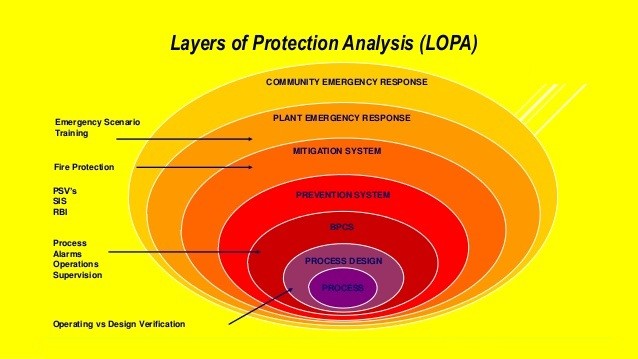

LOPA, which stands for Layers of Protection Analysis, is a systematic and structured approach used in the process industry to assess and quantify the reliability of safety layers that protect against potential hazards. SIL, or Safety Integrity Level, on the other hand, refers to a measure of the effectiveness of these safety layers in reducing risk to an acceptable level. Understanding LOPA & SIL Study is crucial for ensuring safety and reliability in industrial processes. In LOPA, multiple protection layers are identified and analyzed to determine their reliability and effectiveness in preventing or mitigating hazardous events. This analysis involves considering various factors such as failure rates, test intervals, human factors, and management systems. By quantifying these protection layers through SIL levels, organizations can accurately assess the risk reduction achieved by each layer.

The significance of understanding LOPA & SIL Study lies in its ability to provide industries with a comprehensive risk assessment framework. It enables them to identify critical hazards that could potentially lead to accidents or incidents. Moreover, through this study, organizations can optimize their safety systems by identifying areas where additional protection measures are required or where existing measures need improvement. Ultimately, comprehending LOPA & SIL Study allows companies to prioritize their resources effectively and make informed decisions regarding risk management strategies with confidence

Importance of LOPA & SIL Study in the Process Industry

As one delves into the complexities of the process industry, the importance of LOPA (Layer of Protection Analysis) & SIL (Safety Integrity Level) Study becomes glaringly evident. These studies serve as indispensable tools in ensuring safety and reliability within this sector. By thoroughly examining potential hazards and risks, LOPA & SIL Study allows for a comprehensive understanding of critical processes, enabling mitigation measures to be implemented effectively. In today’s fast-paced industrial landscape, where technological advancements are constantly pushing boundaries, LOPA & SIL Study acts as a guiding light that illuminates the path towards enhanced safety standards. With its meticulous analysis and identification of layers of protection, it empowers industries to fortify their systems against potential threats. Moreover, by adopting a proactive approach to risk management through LOPA & SIL Study implementation, companies can instill confidence in both their employees and stakeholders.

By embracing LOPA & SIL Study methodologies, the process industry is poised to achieve remarkable strides in safety and reliability. The knowledge gained from these studies serves as a catalyst for innovation and improvement across all levels of operations. As organizations invest in this robust framework, they sow the seeds for an environment where accidents are minimized and trust is nurtured. Therefore, recognizing the importance of LOPA & SIL Study is not merely an obligation but an opportunity to create safer workspaces that foster growth and prosperity.

Key Components of LOPA & SIL Study

Key Components of LOPA & SIL Study: Within a LOPA (Layers of Protection Analysis) & SIL (Safety Integrity Level) study, several key components are crucial for ensuring the safety and reliability of processes in the process industry. These components serve as the building blocks that form a comprehensive and effective analysis.

1. Hazards Identification: The first step in any LOPA & SIL study is to identify potential hazards within the process industry. This involves a meticulous examination of all possible scenarios that could lead to accidents, incidents, or failures.

2. Risk Assessment: Once hazards are identified, a thorough risk assessment is conducted. This entails evaluating the likelihood and severity of each hazard, determining their potential consequences, and assigning appropriate risk levels.

3. Safeguard Analysis: After risk assessment, it is essential to analyze existing safeguards or protective measures in place to mitigate identified risks. This includes evaluating their effectiveness, reliability, maintenance requirements, and any potential limitations.

4. Safety Integrity Levels (SIL): Determining the required Safety Integrity Levels for each safeguard is another critical component of LOPA & SIL studies. SIL ratings provide quantifiable targets that address specific risk reduction requirements to achieve an acceptable level of safety performance.

5. Independent Protection Layers: In this stage, independent protection layers (IPLs) are identified and evaluated for their ability to prevent or mitigate potential incidents or accidents within the process industry. IPLs act as additional layers of protection beyond inherent safeguards already in place.

By focusing on these key components during a LOPA & SIL study, organizations can effectively assess risks associated with their processes while identifying areas for improvement and implementing robust safety measures that can enhance operational reliability and protect personnel from harm

Conducting a LOPA & SIL Study: Methodology and Steps

Conducting a LOPA & SIL Study: Methodology and Steps Embarking on a LOPA (Layers of Protection Analysis) and SIL (Safety Integrity Level) study requires meticulous planning and execution. The methodology follows a systematic approach to identify potential hazards, assess the adequacy of existing safeguards, and determine the necessary safety integrity levels.

The first step involves forming a multidisciplinary team with expertise in process engineering, risk management, instrumentation, and control systems. This diverse group collaborates to define the scope of the study and establish clear objectives. Thorough documentation of the process under analysis is crucial at this stage.

Next, an initial hazard identification is conducted using techniques such as HAZOP (Hazard and Operability Study), FMEA (Failure Mode and Effects Analysis), or PHA (Process Hazard Analysis). This helps pinpoint scenarios where the process may deviate from its intended design.

Once potential hazards are identified, each scenario undergoes a quantitative risk assessment to estimate its severity, likelihood of occurrence, and detectability. Risk matrices or fault tree analyses are commonly used for this purpose. This step ensures that risks are prioritized based on their criticality.

After determining the risk associated with each scenario, it is necessary to evaluate existing safeguards already in place within the process. These safeguards can be categorized into independent protection layers (IPLs). Their effectiveness is assessed by evaluating factors such as reliability, availability, test intervals, response time, and probability of failure on demand.

The final step involves calculating Safety Integrity Levels (SILs) for each IPL based on established industry standards like IEC 61511 or ANSI/ISA 84.00.01

Case Studies: Successful Implementation of LOPA & SIL Study in the Process Industry

Case Studies: Successful Implementation of LOPA & SIL Study in the Process Industry. In the labyrinth of complex industrial processes, the implementation of LOPA (Layer of Protection Analysis) and SIL (Safety Integrity Level) studies has proven to be a beacon of safety and reliability. Let us delve into two remarkable case studies that showcase the transformative power of these studies in mitigating risks and ensuring operational excellence.

In our first case study, a chemical manufacturing plant faced significant challenges in identifying potential hazards and determining appropriate layers of protection. By conducting a comprehensive LOPA & SIL study, they were able to pinpoint critical areas that required additional safeguards. Through meticulous analysis, they implemented redundant safety systems and enhanced operator training protocols, resulting in a staggering 75% decrease in process-related incidents over the course of two years. This success story not only underscores the effectiveness of LOPA & SIL studies but also highlights their potential to foster a culture of safety within an organization.

Moving on to our second case study, an oil refinery was grappling with recurring equipment failures that posed severe threats to both personnel and infrastructure. By embarking on a LOPA & SIL study journey, they gained invaluable insights into their operational vulnerabilities and devised robust mitigation strategies accordingly. Utilizing advanced risk assessment techniques, they restructured their maintenance practices and introduced proactive monitoring systems. Consequently, unplanned shutdowns were drastically minimized by 80%, generating substantial cost savings while bolstering overall plant efficiency.

These case studies illuminate how LOPA & SIL studies can be instrumental in revolutionizing process industry operations by instilling confidence, reducing incidents, improving productivity, and safeguarding both human lives and valuable assets

Benefits of LOPA & SIL Study for Safety and Reliability

LOPA & SIL Study offers a multitude of benefits for ensuring safety and reliability in the process industry. Firstly, it provides a systematic approach to identify and analyze potential hazards, enabling organizations to proactively mitigate risks. By conducting a LOPA & SIL Study, companies can gain valuable insights into their safety systems, leading to enhanced operational efficiency and reduced incidents. Furthermore, LOPA & SIL Study promotes a culture of continuous improvement in safety practices. It encourages organizations to regularly review and update their safety measures based on the study’s findings. This iterative process ensures that any gaps or vulnerabilities within the system are promptly addressed, resulting in increased reliability and reduced downtime.

Lastly, implementing LOPA & SIL Study demonstrates a strong commitment to the well-being of employees and the surrounding community. By embracing a proactive approach to risk management, companies create an environment where safety is prioritized above all else. This fosters trust among stakeholders, enhances reputation, and ultimately contributes to a more sustainable and prosperous future for all involved.

Challenges and Limitations in Performing LOPA & SIL Study

Navigating the intricate terrain of LOPA & SIL Study in the process industry does not come without its fair share of challenges and limitations. One such hurdle lies in data availability and quality. Adequate historical data may be lacking, making it difficult to accurately assess the frequency and consequences of potential hazards. However, this drawback can be addressed by leveraging advanced data collection techniques and collaborating with relevant stakeholders to gather comprehensive information. Another challenge is the inherent subjectivity involved in LOPA & SIL Study. Different experts may have varying opinions on risk levels, acceptable tolerability criteria, or consequence severity assessments. To overcome this, it is crucial to establish a transparent decision-making process that encourages interdisciplinary collaboration and fosters consensus among all parties involved. By doing so, a more robust assessment can be achieved, thereby enhancing safety and reliability.

Moreover, one must also acknowledge the limitations imposed by time and resources when conducting LOPA & SIL Study. The detailed analysis required often demands significant investments of both time and manpower. However, embracing technological advancements such as software tools that facilitate efficient risk analysis can streamline the process while ensuring accurate results within specified timelines.

Despite these challenges and limitations, it is paramount to approach them as opportunities for growth rather than deterrents. By acknowledging these barriers upfront and proactively addressing them through collaborative efforts, organizations can pave the way for safer operations while instilling a sense of collective responsibility towards ensuring safety and reliability in the process industry landscape of India.

Integration of LOPA & SIL Study into Process Safety Management

Integration of LOPA & SIL Study into Process Safety Management: The seamless integration of LOPA (Layers of Protection Analysis) and SIL (Safety Integrity Level) study within the realm of process safety management is paramount for ensuring a robust safety framework in the process industry. By incorporating these two methodologies, organizations can identify and mitigate potential hazards while enhancing overall operational reliability.

When it comes to integrating LOPA & SIL study into process safety management, a multidisciplinary approach is essential. Representatives from various departments, such as engineering, operations, maintenance, and HSE (Health, Safety, and Environment), must collaborate harmoniously. This collaborative effort enables the identification of critical scenarios, evaluation of protective layers’ effectiveness, and determination of target SIL levels for each hazard.

Moreover, this integration allows organizations to holistically assess risks across the entire lifecycle of a process facility. From design and construction to operation and decommissioning phases, LOPA & SIL study becomes an integral part of decision-making processes at every stage. Through this holistic approach to process safety management, companies can optimize their operational strategies while prioritizing personnel safety.

By embracing the integration of LOPA & SIL study into process safety management practices, organizations not only comply with regulatory requirements but also foster a culture centered around continuous improvement in safety performance. This proactive approach empowers employees at all levels to actively engage in risk assessment activities and contribute their insights towards enhancing overall safety measures. Ultimately, this integration paves the way for safer work environments that inspire confidence among stakeholders while fostering sustainable growth within the process industry.

Compliance with Indian Regulatory Standards and Guidelines

Compliance with Indian Regulatory Standards and Guidelines: In the realm of process safety, adherence to regulatory standards and guidelines is paramount to ensure the well-being of both workers and the environment. In India, the process industry is subject to stringent regulations set forth by various authorities such as the Ministry of Environment, Forests, and Climate Change (MoEFCC), Central Pollution Control Board (CPCB), and Directorate General of Factory Advice Service and Labour Institutes (DGFASLI). These regulations aim to foster a culture of safety, emphasizing the prevention of accidents through robust risk analysis methodologies like LOPA & SIL Study.

To comply with Indian regulatory standards, organizations operating in the process industry must conduct thorough assessments using LOPA & SIL Study techniques. This involves analyzing different layers of protection in place for each identified hazardous scenario while considering their reliability and effectiveness. By doing so, organizations can demonstrate their commitment to mitigating risks proactively while ensuring compliance with Indian regulatory requirements.

Furthermore, by aligning with Indian regulatory standards, companies not only uphold legal obligations but also enhance their reputation within the industry. Adhering to these guidelines fosters trust among stakeholders by assuring them that safety measures are being implemented meticulously. In turn, this helps attract investors who value responsible practices and promotes a positive perception of businesses operating in the process industry in India.

Best Practices for Conducting LOPA & SIL Study in the Process Industry

Best Practices for Conducting LOPA & SIL Study in the Process Industry: First and foremost, meticulous planning is essential. Begin by assembling a competent team comprising individuals with expertise in process safety, engineering, and risk assessment. Clearly define the scope of the study, including all processes and potential hazards to be examined.

Next, gather accurate and up-to-date data on process parameters, equipment specifications, and operational procedures. It is crucial to involve relevant stakeholders to ensure a comprehensive understanding of the system being analyzed.

During the study, encourage open communication and collaboration among team members. Foster an environment that values diverse perspectives and encourages constructive criticism. This approach promotes thorough analysis of potential scenarios while ensuring that no critical aspect is overlooked.

Additionally, prioritize transparency throughout the entire study process. Document all assumptions made during calculations and clearly state any uncertainties or limitations encountered.

By adhering to these best practices, organizations can conduct robust LOPA & SIL studies that facilitate informed decision-making regarding safety measures. Emphasizing careful planning, effective communication, and transparency will not only enhance reliability but also cultivate a culture of safety within the industry as a whole.

Conclusion

In conclusion, the LOPA & SIL Study is an indispensable tool for ensuring safety and reliability in the process industry of India. Through its meticulous methodology and comprehensive analysis, it enables organizations to identify and mitigate risks effectively, thereby safeguarding human lives, the environment, and assets. The successful implementation of LOPA & SIL Study in various case studies highlights its potential in minimizing incidents and enhancing overall operational excellence. As India’s process industry continues to evolve, embracing LOPA & SIL Study as an integral part of process safety management will undoubtedly pave the way for a safer and more prosperous future.