Fire And Gas Mapping Solution

Fixed flame and gas detector systems are designed and installed to protect large and complex areas filled with process equipment from risks of combustible or toxic gas leaks, explosions, and flames. For these systems to be effective, it is important that they offer a high likelihood of detecting the presence of flame and gas hazards within monitored process areas. Determining the optimal quantity and location of flame and gas detectors is therefore critical to ensure the detection system’s effectiveness.

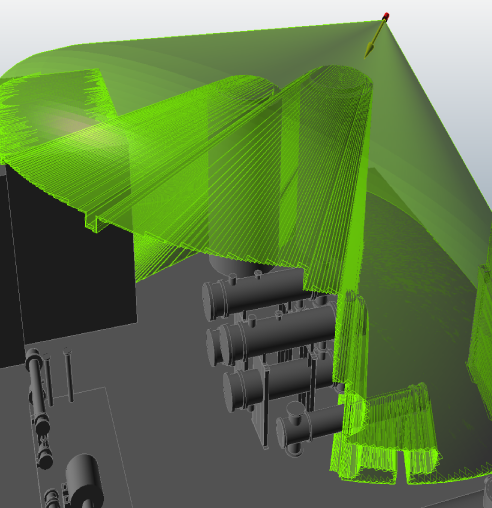

The Safety Master flame and gas mapping is a solution that assists in the evaluation of flame and gas risks within a processing facility and reducing these risks towards an acceptable risk profile. Flame and gas mapping includes placing detectors in appropriate locations to achieve the best possible detection coverage.

Significance of undertaking F & G Mapping?

Major oil corporations extended ‘ISA TR84.00.07 steering on the Effectiveness of fireside and Gas Detection’ to handle the logic question of “How several detectors are needed in dangerous facility & wherever to position it all?”- F&G Mapping permits the designer to position flame and gas detection devices at intervals the facility and assess the coverage afforded by the system. This can be mechanically correlative against pre-specified targets that the system should achieve.

- F&G Mapping does not only give edges during the planning section. The benefits of F&G Mapping may be observed in an exceeding range of ways throughout the operational section.

- F&G Mapping provides designers with the methodology and tools to review detection coverage against pre-determined targets and guarantee an appropriate and optimized system is commissioned.

- One of the first deliverables of an adequate F&G Mapping study is elaborate detector contributions and permits for that crucial maintenance optimization perform. Therefore, F&G Mapping conjointly provides the numerous good thing about maintenance optimization, which might save cash and doubtless lives.