Navigating Regulatory Requirements in Electrical Safety Audit

What is HAZOP? A Complete Guide to Hazard and Operability Study by The Safety Master

March 14, 2025

Fire Audit of building or manufacturing units

March 18, 2025Introduction

Electrical safety audits are essential for ensuring that electrical systems comply with regulatory standards, minimize risks, and protect both personnel and property. Navigating regulatory requirements can be complex, but it is crucial for maintaining safety and avoiding legal repercussions. In this guide, we will delve into the best practices for conducting electrical safety audits with a focus on adhering to regulatory requirements.

Understanding Electrical Safety Audits

Definition and Purpose of Electrical Safety Audits

Electrical safety audits involve a systematic evaluation of electrical systems, equipment, and practices to ensure they meet safety standards and regulations. The primary purpose is to identify hazards, mitigate risks, and ensure a safe working environment.

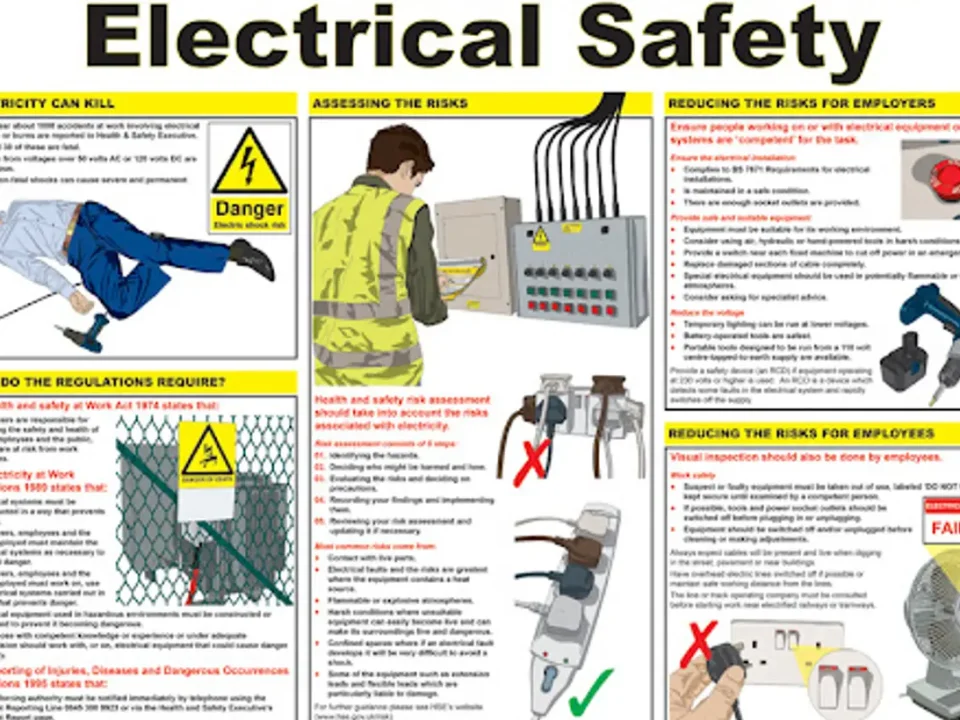

Importance of Regulatory Compliance

Compliance with electrical safety regulations is crucial to prevent accidents, injuries, and legal issues. Regulatory compliance ensures that organizations adhere to established safety standards, protecting employees and reducing liability.

Key Regulations and Standards

- NFPA 70E: Standard for Electrical Safety in the Workplace.

- OSHA 29 CFR 1910: Occupational Safety and Health Administration regulations for electrical safety.

- IEC 60364: International standards for electrical installations.

- NEC (National Electrical Code): Standards for safe electrical design, installation, and inspection.

Preparing for an Electrical Safety Audit

Setting Clear Objectives

Define the objectives of the audit clearly. Objectives may include ensuring compliance with specific regulations, identifying potential hazards, and improving overall safety practices.

Selecting a Competent Audit Team

Choose an audit team with expertise in electrical safety, regulatory knowledge, and auditing skills. Ensure the team is well-trained and experienced in conducting thorough and effective audits.

Creating a Detailed Audit Plan

Develop a comprehensive audit plan outlining the scope, objectives, methodology, and timeline. Include specific checklists and guidelines to ensure a systematic and consistent audit process.

Conducting the Audit

Initial Risk Assessment

Perform an initial risk assessment to identify potential hazards and areas of focus. This helps prioritize efforts and allocate resources effectively.

On-site Inspections and Testing

Conduct thorough on-site inspections and testing of electrical systems and equipment. Check for compliance with safety standards, proper installation, maintenance, and operational practices.

Documentation Review

Review relevant documentation such as electrical schematics, maintenance records, incident reports, and training logs. Ensure all documents are accurate, up-to-date, and compliant with regulatory requirements.

Interviews and Observations

Interview employees and observe work practices to assess their understanding of electrical safety procedures and compliance with safety standards.

Evaluating Compliance

Identifying Non-compliance Issues

Identify any non-compliance issues with regulatory standards or internal safety procedures. Document these findings systematically for further analysis.

Assessing Risk Levels

Evaluate the risk levels associated with each non-compliance issue. Consider the potential impact on safety, operations, and regulatory compliance.

Prioritizing Compliance Actions

Prioritize compliance actions based on the severity and risk levels of the identified issues. Focus on high-risk areas that require immediate attention.

Reporting and Follow-up

Preparing the Audit Report

Compile a detailed audit report outlining findings, risk assessments, and recommended corrective actions. Include evidence such as photographs, documents, and observation notes.

Communicating Audit Findings

Communicate the audit findings to relevant stakeholders, including management, employees, and regulatory bodies. Ensure transparent and effective communication to foster a culture of safety and compliance.

Implementing Corrective Actions

Develop and implement corrective actions to address the identified non-compliance issues. Assign responsibilities and set deadlines for completing these actions.

Follow-up Audits

Conduct follow-up audits to verify the implementation and effectiveness of corrective actions. Schedule regular re-audits to ensure continuous compliance and improvement.

Best Practices for Regulatory Compliance

Continuous Education and Training

Provide continuous education and training for employees and auditors on the latest electrical safety regulations, standards, and best practices. Ensure ongoing competency and awareness.

Utilizing Advanced Technologies

Leverage advanced technologies such as audit management software, mobile inspection tools, and data analytics to enhance the efficiency and accuracy of the audit process.

Promoting a Safety Culture

Promote a culture of safety within the organization by encouraging proactive safety practices, open communication, and continuous improvement. Foster a commitment to regulatory compliance and risk mitigation.

Challenges and Solutions

Common Challenges in Electrical Safety Audits

- Keeping up with Regulatory Changes: Regularly changing regulations can be challenging to track and implement.

- Resource Constraints: Limited resources can hinder the thoroughness of the audit process.

- Employee Resistance: Employees may resist changes or fail to adhere to safety procedures.

Strategies to Overcome Barriers

- Staying Informed: Regularly update knowledge on regulatory changes through training and professional networks.

- Efficient Resource Allocation: Prioritize high-risk areas and allocate resources strategically.

- Employee Engagement: Involve employees in safety initiatives and provide incentives for compliance.

Case Studies

Examples of Successful Compliance

- Case Study 1: A manufacturing plant implemented comprehensive electrical safety audits, resulting in a significant reduction in electrical incidents and enhanced compliance with NFPA 70E.

- Case Study 2: An industrial facility utilized advanced technology for continuous monitoring and auditing, leading to improved safety practices and regulatory adherence.

Lessons Learned

- Proactive Approach: Proactive safety measures and regular audits are crucial for maintaining compliance and preventing incidents.

- Employee Involvement: Engaging employees in safety initiatives fosters a culture of compliance and continuous improvement.