Process Safety Management By The Safety Master

Process Safety Management (PSM) is a comprehensive approach aimed at preventing accidents, particularly in industries dealing with hazardous chemicals. What is process safety management? It involves integrating management practices, technologies, and procedures to ensure the safe operation of processes. The core idea behind process safety management is to safeguard employees, the environment, and assets from the risks associated with industrial processes. By answering the question what is process safety management, businesses can understand the importance of safety protocols and how they help in mitigating risks. The PSM definition reflects the need for meticulous planning and ongoing efforts to maintain a safe working environment.

Why is understanding the definition of Process Safety Management crucial for industries?

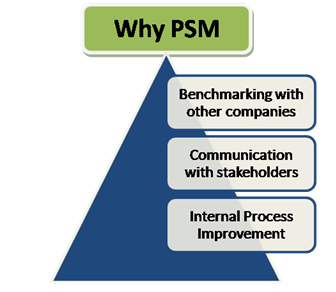

Understanding the PSM definition is essential for industries because it highlights the need for a structured approach to safety. When industries comprehend what is process safety management, they can better implement strategies that protect their workforce and assets. The PSM definition serves as a foundation for establishing safety protocols and ensures that industries adhere to regulations. By embracing process safety management, companies can prevent catastrophic incidents and maintain operational efficiency. Therefore, knowing the PSM definition and understanding its implications is crucial for industry leaders.

How does Process Safety Management ensure workplace safety?

Process safety management plays a pivotal role in ensuring workplace safety. By implementing the various process safety management elements, companies can identify and control hazards before they lead to accidents. The PSM definition emphasizes the importance of maintaining safe processes, which in turn protects employees and the environment. Through PSM training, workers are educated on safety practices, reducing the likelihood of human error. Overall, process safety management creates a culture of safety, where every individual understands their role in maintaining a secure workplace.

What does Process Safety Management involve?

PSM (Process Safety Management) is a vital component of any process safety management program. It involves educating employees about the process safety management elements and how they apply to their specific roles. PSM (Process Safety Management) covers topics like process hazard analysis, emergency response procedures, and equipment maintenance. The goal of PSM (Process Safety Management) is to ensure that all personnel are competent in identifying and mitigating risks. By investing in PSM (Process Safety Management) , companies can enhance their safety culture and ensure that everyone is prepared to handle potential hazards.

How can businesses implement Process Safety Management effectively?

Implementing process safety management effectively requires a systematic approach. First, businesses need to understand what is process safety management and its significance. Then, they should establish the necessary process safety management elements, such as conducting a thorough process hazard analysis and developing robust operating procedures. Regular PSM training should be provided to keep employees informed about safety practices. Additionally, continuous monitoring and reviewing of process safety management elements are essential to ensure that safety protocols remain up-to-date and effective. By following these steps, businesses can successfully implement process safety management and create a safer work environment.

What are the benefits of adhering to Process Safety Management standards?

Adhering to process safety management standards offers numerous benefits. Firstly, it reduces the risk of accidents, thereby protecting employees and assets. The PSM definition emphasizes prevention, which means fewer disruptions to operations. Secondly, complying with process safety management standards ensures that businesses meet regulatory requirements, avoiding potential fines and legal issues. Finally, a strong process safety management program can enhance a company's reputation, demonstrating a commitment to safety and responsibility. Overall, following process safety management standards leads to a more efficient and safer operation.

How does Process Safety Management fit within regulatory frameworks?

Process safety management is deeply embedded within various regulatory frameworks, such as OSHA's Process Safety Management Standard. The PSM definition aligns with these regulations by emphasizing the need for a structured approach to managing hazardous processes. Understanding what is process safety management helps businesses comply with these standards and avoid penalties. Additionally, the process safety management elements are designed to meet or exceed regulatory requirements, ensuring that companies are always in line with legal obligations. Therefore, process safety management not only enhances safety but also ensures compliance with industry regulations.

What are the common challenges in Process Safety Management implementation?

Implementing process safety management can come with several challenges. One common issue is ensuring that all employees fully understand what is process safety management and its importance. Inadequate PSM training can lead to misunderstandings and gaps in safety protocols. Additionally, maintaining the process safety management elements requires ongoing effort and resources, which can be challenging for some organizations. Resistance to change is another obstacle, as some employees may be reluctant to adopt new safety procedures. However, with proper PSM training and a strong commitment from leadership, these challenges can be overcome.

How can ongoing Process Safety Management training improve safety outcomes?

Ongoing PSM training is crucial for improving safety outcomes. Continuous education ensures that employees stay updated on the latest process safety management elements and best practices. Regular PSM training sessions help reinforce the PSM definition and the importance of following safety protocols. By keeping safety top-of-mind, companies can reduce the risk of accidents and improve overall safety performance. Process safety management is not a one-time effort but an ongoing commitment, and regular PSM training plays a key role in maintaining a safe and compliant workplace.

The Safety Master: Premier Process Safety Management Training

Process Safety Management (PSM) plays a crucial role in industries dealing with hazardous chemicals, ensuring rigorous protocols are followed to minimize risks and prevent major incidents. At The Safety Master, we recognize the significance of comprehensive training in this area and have developed a specialized program tailored to meet the highest safety and compliance standards.

Our training is structured to deliver a deep understanding of essential methodologies such as Hazop Study, empowering professionals to proactively identify and manage potential process hazards.

For organizations aiming to strengthen their safety infrastructure, this program also supports broader initiatives including Fire Audit and Safety Audit procedures. Led by experienced experts, each session is guided by a dedicated Safety Consultant to ensure actionable insights and real-world application, ultimately protecting both personnel and the environment.

Drawing from industry-leading practices and standards, The Safety Master's training program covers all crucial aspects of process safety management. Our curriculum is influenced by the collaborative efforts seen in leading qualifications like the NEBOSH HSE Certificate in Process Safety Management, which merges technical expertise with vocational training excellence. Similarly, our program integrates insights from the systematic approaches employed by top safety management frameworks, ensuring a holistic and thorough education in PSM.

Comprehensive Curriculum

Our training is structured into multiple modules, each targeting specific elements of Process Safety Management. Participants will gain a deep understanding of process design, technology, operational activities, and maintenance procedures. We emphasize the importance of emergency preparedness, non-routine operations, and the development of a safety culture within the organization. Our modules are designed to be rigorous yet achievable, ensuring participants can practically apply the knowledge gained.

Contact us for inquiry on Process Safety Management Training & Certification Services for your engineers or staff.Its 2 days certification training program.

Module Breakdown:

Commit to Process Safety:

Establishing a robust process safety culture. Ensuring compliance with international and local safety standards. Building competency in process safety among employees. Encouraging workforce involvement and stakeholder outreach. Understand Hazards and Risk:

Comprehensive process knowledge management. Effective hazard identification and risk analysis techniques. Manage Risk:

Developing and implementing safe operating procedures. Establishing safe work practices and ensuring asset integrity. Managing contractor safety and ensuring operational readiness. Addressing management of change and conducting operational safety reviews. Planning and executing emergency management strategies. Learn from Incidents:

Conducting thorough incident investigations. Implementing measurement and metrics for process safety performance. Regular auditing and management review for continuous improvement. Learning Outcomes

Participants in The Safety Master’s Process Safety Management Training will:

Identify and assess major accident hazards within their facilities.

Develop and utilize critical controls to mitigate risks.

Gain hands-on experience with tools such as bowtie diagrams for risk analysis.

Understand the dynamic and static aspects of barrier management.

Learn to manage risks across various operational phases, from routine operations to new projects. Training Delivery and Customization

Our training is flexible and can be customized to meet the specific needs of our clients. We offer both classroom and virtual training options, ensuring accessibility for participants regardless of location. The classroom training spans five days, combining interactive lectures with practical breakout sessions. Alternatively, our virtual program extends over several weeks, incorporating online lectures, offline assignments, and interactive feedback sessions.

The Safety Master’s training program stands out due to our commitment to quality and our deep industry expertise. Our trainers are seasoned professionals with extensive experience in process safety, bringing practical insights and authoritative knowledge to the training sessions. This ensures that participants receive the most current and relevant information, grounded in real-world applications.

By choosing The Safety Master, organizations can trust that they are receiving a Process Safety Management Training program that is not only comprehensive but also aligned with the best practices and standards in the industry. Our focus on experience, expertise, authoritativeness, and trustworthiness ensures that your organization will be well-equipped to handle process safety challenges effectively, thereby safeguarding your operations and workforce.