Compliance Today, Continuity Tomorrow: Why Safety is Your Best Business Strategy

The Domino Effect: How a Single Unsafe Act Can Shut Down Your Entire Plant

January 6, 2026

The 3-Year Danger Zone: Why Your Outdated Safety System is a Liability

February 6, 2026In the fast-paced world of Indian industry, “Safety” is often relegated to a checklist—a series of forms to be filled out to satisfy a government inspector or a set of rules posted on a notice board that everyone walks past but rarely reads.

However, at The Safety Master, we see things differently. We believe that safety is not just about avoiding fines or ticking boxes; it is the very backbone of your business survival. The mantra “Compliance Today. Continuity Tomorrow” isn’t just a catchy tagline; it is a fundamental economic truth.

If you are a plant manager, a business owner, or an EHS officer in India, you know the pressure of production targets. But have you calculated the cost of silence? The silence of a factory floor halted by an accident? The silence of a reputation damaged beyond repair? This article explores why rigorous compliance today is the only way to guarantee you have a business to run tomorrow.

The Illusion of “Good Enough”

Many organizations fall into the trap of doing the bare minimum. They comply with the basic requirements of the Factories Act, 1948, or state-specific rules, just enough to get the license renewed. This is a reactive approach. It views safety as a cost center—a burden that eats into profits.

But let’s flip the perspective.

Imagine your facility is a high-performance athlete. You wouldn’t feed an athlete junk food and expect them to win a marathon just because they “look” healthy on the outside. Similarly, a facility that ignores deep-rooted safety culture because it “looks” compliant on paper is prone to catastrophic injury.

Compliance is the health checkup. Continuity is the lifespan.

When you cut corners on compliance today, you are borrowing time from tomorrow at a very high interest rate. Eventually, the debt comes due in the form of equipment failure, fire incidents, or tragic loss of life.

The Fire Risk: More Than Just Extinguishers

Fire is perhaps the single greatest threat to business continuity in India. We have seen countless headlines where thriving businesses were reduced to ashes in a matter of hours, often due to preventable electrical short circuits or poor storage of flammable materials.

Many business owners believe that having a few red cylinders hanging on the wall means they are safe. This is a dangerous misconception. Fire safety is a complex ecosystem involving detection, suppression, evacuation, and containment.

This is where a professional approach becomes non-negotiable. It is not enough to simply have equipment; you must verify that the equipment works, that your people know how to use it, and that your building’s layout supports rapid evacuation. Conducting a comprehensive Fire Audit allows you to see the invisible risks. It moves beyond the surface level to inspect your electrical loads, the functionality of your hydrant systems, and the compliance of your building with the National Building Code (NBC) 2016.

A proper audit identifies the gaps between “perceived safety” and “actual safety.” If a fire breaks out, compliance ensures your sprinklers trigger. Continuity ensures your factory is still standing the next day so your workers have jobs to return to.

The General Health of Your Facility

While fire is a high-visibility risk, the silent killers of business continuity are often the mundane hazards: a slippery floor, an unguarded machine, a corroded support beam, or a lack of Personal Protective Equipment (PPE).

In the Indian manufacturing sector, the diversity of risk is immense. A textile mill faces different threats than an automotive assembly line. However, the result of neglecting these risks is always the same: downtime.

If a worker is injured due to a lack of machine guarding, the immediate consequence is the tragedy of human suffering. The secondary consequence is the stop-work order, the police investigation, the legal battles, and the morale crash among the remaining workforce.

To prevent this, organizations must move from “correcting” problems to “finding” them before they manifest. A holistic Safety Audit acts as a deep-dive diagnostic tool. It evaluates your Safety Management System (SMS) against international standards (like ISO 45001) and local Indian regulations (like The Factories Act). It examines your permits to work, your lockout-tagout (LOTO) procedures, and your behavioral safety culture.

By identifying these hazards proactively, you aren’t just complying with the law; you are ensuring that your production line never stops due to an avoidable error.

Taming the Beast: Process Safety in High-Risk Industries

For industries dealing with hazardous chemicals, oil and gas, or pharmaceuticals, the stakes are exponentially higher. Here, we aren’t just talking about occupational injuries; we are talking about catastrophic events that can affect entire communities. The legacy of tragedies like Bhopal serves as a somber reminder of what happens when process controls fail.

In these environments, standard safety measures are insufficient. You need a disciplined framework for managing the integrity of operating systems and processes handling hazardous substances. This is where Process Safety Management (PSM) comes into play.

PSM is about keeping the “beast” in the cage. It involves rigorous analysis of process hazards (using tools like HAZOP), managing change (MOC) so that a simple valve replacement doesn’t trigger an explosion, and ensuring mechanical integrity.

For a chemical plant, compliance might mean submitting the necessary environmental forms. But continuity relies on PSM. If a containment vessel fails, it doesn’t matter how compliant your HR policies are—your business may cease to exist. Implementing robust PSM is the ultimate insurance policy for high-hazard sectors, ensuring that volatile materials result in profit, not disaster.

The Economics of Continuity

Let’s talk numbers, because business decisions are ultimately driven by the bottom line.

There is a concept in safety management called the “Iceberg Theory” of accident costs.

- The Tip of the Iceberg (Direct Costs): Medical bills, compensation, damaged equipment. These are insured and visible.

- The Submerged Mass (Indirect Costs): These are uninsurable and can be 10 to 50 times higher than direct costs.

- Lost production time.

- Training replacement employees.

- Investigation time.

- Reputation damage.

In the digital age, news travels instantly. If your facility has a major safety breach, your clients (especially international buyers with strict ESG requirements) may pull their contracts. Investors may withdraw capital. The community may protest your operations.

Compliance costs money. Non-compliance costs the business.

Investing in safety today is actually an investment in operational efficiency. A safe plant is usually a clean, well-organized, and efficient plant. When workers feel safe, they are more productive and engaged. When processes are audited and streamlined, downtime decreases.

Building a Culture, Not Just a Wall

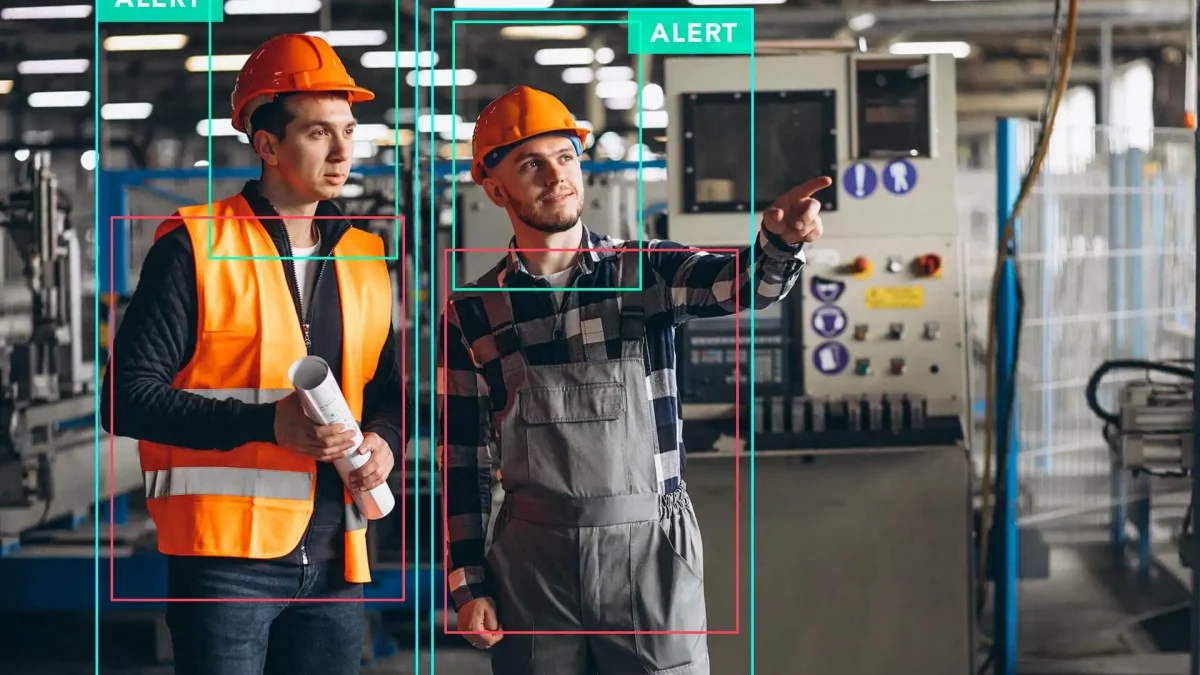

At The Safety Master, we often see companies trying to “buy” safety. They purchase the most expensive helmets or install the latest sensors, but they fail to train their people.

Compliance is often static—it’s a rule written on paper. Continuity is dynamic—it’s a culture living in your people.

To bridge the gap between compliance and continuity, you need to engage the workforce. The worker on the shop floor is the first person to notice a vibrating motor or a smell of gas. If your culture encourages them to speak up without fear of retribution, you have a powerful early warning system.

Steps to Shift the Paradigm:

- Leadership Commitment: Safety starts in the boardroom. If the Director doesn’t wear a helmet, the supervisor won’t either.

- Regular Audits: Don’t wait for the government inspector. Schedule voluntary third-party audits to get an unbiased view of your risks.

- Training: Move beyond boring lectures. conduct drills, simulations, and interactive workshops.

- Reward Safety: Celebrate “near-miss” reporting. If someone reports a hazard, thank them. They just saved you from a potential accident.

The Future of Indian Industry

India is poised to become a global manufacturing hub. With initiatives like “Make in India,” we are seeing larger, more complex industrial setups. With this growth comes increased scrutiny.

Global supply chains demand resilience. International partners want to know that your factory won’t shut down next month due to a regulatory ban or a fire. They are looking for partners who view safety as a core value, not a hurdle.

By embracing the philosophy of “Compliance Today, Continuity Tomorrow,” you are positioning your organization as a leader. You are telling your employees, your investors, and your customers that you are here to stay.

At The Safety Master, we are dedicated to helping Indian industries navigate this journey. Whether it is through specialized audits, training, or consulting, we help you build the bridge between meeting the law and securing your future.

Safety isn’t expensive. It’s priceless. Let’s build a safer, more sustainable industrial India, one audit at a time.