Electrical Safety Audit: Process, Steps & Compliance in India

Transportation Route Risk Assessment and Logistics Safety Audit

September 23, 2025

How AI & Predictive Analytics Are Transforming Safety Audits in 2025

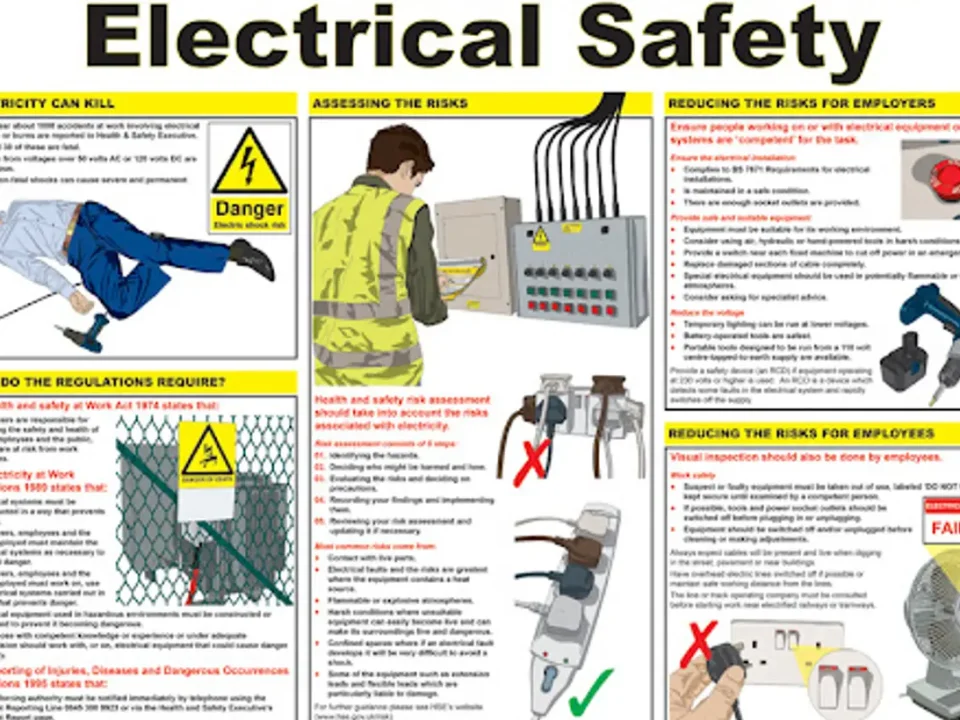

September 24, 2025An Electrical Safety Audit is a structured inspection and testing process carried out to ensure the safety, compliance, and reliability of electrical systems. It helps organizations identify potential hazards, reduce risks of electrical shock and fire, and comply with standards such as the Indian Electricity Rules, IS 732, and IS 3043.

By conducting an audit, companies can enhance workplace safety, prevent accidents, and comply with regulatory requirements.

Key Steps in Conducting an Electrical Safety Audit

1. Define Scope and Objectives

Clearly define which areas, systems, or equipment will be covered in the audit. Set objectives like compliance verification, hazard identification, or fire and shock risk assessment.

2. Assemble the Audit Team

Form a team of qualified professionals with expertise in electrical safety, testing tools, and national/international safety standards.

3. Review Documentation

Examine documents such as electrical schematics, maintenance records, past audit reports, and workplace safety policies.

4. Develop an Audit Checklist

Create a detailed checklist to ensure that every component—wiring, panels, grounding, insulation, and protective devices—is systematically evaluated.

5. On-Site Inspection

Carry out physical inspections of electrical panels, distribution boards, outlets, machinery, and grounding systems to check for wear, damage, or overloading.

6. Testing and Measurement

Use modern tools like infrared thermal cameras, insulation resistance testers, and ground fault measurement devices to detect issues such as overheating or weak insulation.

7. Hazard and Risk Assessment

Identify hazards related to electric shock, fire, arc flash, and static electricity. Assess their severity and recommend preventive actions.

8. Compliance Verification

Check whether installations and systems meet Indian standards (IS 732, IS 3043) as well as relevant international electrical safety codes.

9. Review Safety Procedures

Evaluate workplace practices such as lockout/tagout (LOTO), work permit systems, and the use of Personal Protective Equipment (PPE).

10. Compile the Audit Report

Prepare a comprehensive report that highlights:

- Audit findings

- Non-compliances and risks

- Recommendations for corrective action

11. Implement Corrective Actions

Address deficiencies promptly by repairing faulty systems, updating safety protocols, and training staff.

12. Follow-Up and Continuous Improvement

Schedule follow-up audits to track improvements and build a cycle of continuous safety monitoring.

Why Electrical Safety Audits are Important

- Prevent accidents caused by electrical faults

- Ensure compliance with statutory and industrial safety regulations

- Protect people, property, and equipment

- Improve system reliability and reduce downtime

- Build a culture of workplace safety

✅ Conducting regular Electrical Safety Audits not only ensures compliance but also strengthens an organization’s safety framework. By following the audit process step by step, businesses can achieve safer operations, reduce risks, and maintain regulatory adherence.