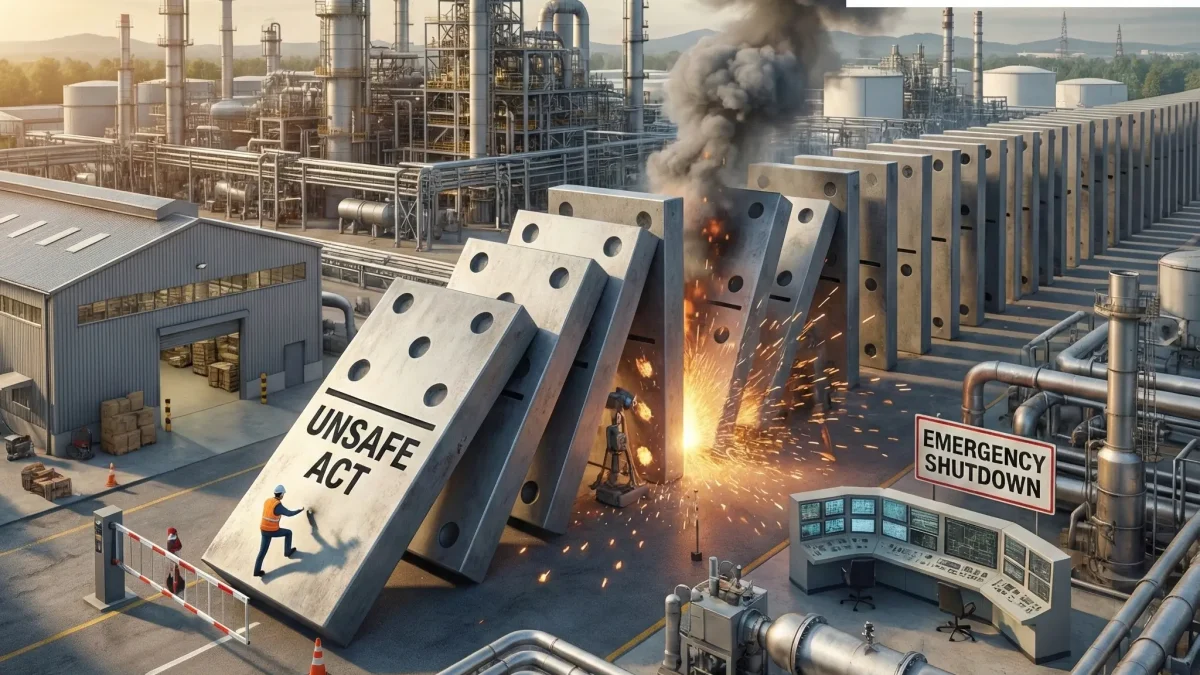

The Domino Effect: How a Single Unsafe Act Can Shut Down Your Entire Plant

Safety Is Not a Cost. It’s Business Continuity.

January 5, 2026

Compliance Today, Continuity Tomorrow: Why Safety is Your Best Business Strategy

February 2, 2026Imagine the sound of your manufacturing plant at full capacity. It is a symphony of productivity: the hum of conveyors, the rhythmic clanking of presses, the hiss of hydraulics. It is the sound of revenue being generated.

Not the peaceful silence of a holiday, but the heavy, oppressive silence of an unplanned shutdown. The machines are cold. The workers are standing idle or being sent home. Government inspectors are walking the floor with clipboards. Lawyers are on the phone. This isn’t a recession or a supply chain issue; this is the result of a single moment. One split-second decision by an employee to bypass a guard, ignore a sensor, or skip a safety check.

The premise that “One Unsafe Act Can Shut Down Your Plant” is not fear-mongering; it is a statistical and operational reality in the industrial world. In this article, we will explore the anatomy of an unsafe act, the catastrophic ripple effects it creates, and how comprehensive safety strategies—from behavioral training to technical audits—can safeguard your business continuity.

1. The Anatomy of an Unsafe Act

To prevent the shutdown, we must first understand the trigger. In industrial safety, incidents are generally caused by two factors: Unsafe Conditions (environmental hazards like a wet floor or faulty wiring) and Unsafe Acts (human behaviors).

Research consistently shows that 80% to 90% of all workplace accidents are triggered by unsafe acts.

What Does an Unsafe Act Look Like?

An unsafe act is any behavior that deviates from accepted safety protocols, increasing the likelihood of an accident. It is rarely malicious; often, it is a calculated risk taken by a worker to save time or effort. Common examples include:

- Bypassing Safety Devices: Removing machine guards or taping down “dead man” switches to keep machines running without manual input.

- Improper Use of PPE: Wearing a helmet loosely, skipping safety goggles for a “quick job,” or using the wrong type of gloves for chemical handling.

- Operating Without Authority: Using heavy machinery (like forklifts) without proper certification or authorization.

- Speeding or Rushing: Running in industrial areas or increasing machine speeds beyond rated capacities to meet production quotas.

- Horseplay: Distracting co-workers in high-risk zones.

The Psychology Behind the Act

Why would a skilled worker jeopardize their safety and the plant’s operations? The answer usually lies in complacency or production pressure. When a worker performs an unsafe act (like unjamming a machine without locking it out) and doesn’t get hurt, they are psychologically reinforced to do it again. They think, “I did it yesterday, and I was fine.” This creates a ticking time bomb.

2. The Ripple Effect: From a Cut Finger to a Padlocked Gate

It is easy to underestimate a minor safety violation. A manager might see a worker not wearing safety glasses and think, “Well, the worst that can happen is an eye injury.” While an eye injury is tragic for the individual, the manager often fails to see the systemic risk.

Here is how a single unsafe act escalates into a full plant shutdown:

Phase 1: The Immediate Incident

Let’s look at a hypothetical scenario. A maintenance worker decides to skip the “Lockout/Tagout” (LOTO) procedure because the repair will only take two minutes. This is the Unsafe Act. Suddenly, the machine energizes. The worker is severely injured.

Immediate Impact:

- Production on that line stops instantly.

- Emergency services arrive.

- The area is cordoned off as a crime scene/investigation site.

- The entire shift is traumatized, killing morale and focus.

Phase 2: The Regulatory Freeze

Once a serious injury or fatality occurs, regulatory bodies (such as the Factory Inspectorate in India or OSHA globally) step in.

- Stop-Work Orders: Inspectors have the authority to issue immediate prohibition notices. If they suspect that the unsafe act was not an isolated incident but a symptom of a lack of training or supervision, they can shut down not just the specific machine, but the entire section or plant until an investigation is complete.

- Seizure of Equipment: Machinery involved in the accident may be seized or sealed for forensic analysis, leaving you unable to fulfill orders.

Phase 3: The Financial Hemorrhage

While the plant is silent, the costs are screaming.

- Direct Costs: Medical expenses, compensation, and legal fees.

- Indirect Costs: These are often 4 to 10 times higher than direct costs. They include lost production time, spoiled raw materials (if the line stopped mid-process), and overtime pay to catch up later.

- Contractual Penalties: If the shutdown causes you to miss delivery deadlines for key clients, you face late penalties or, worse, contract termination.

Phase 4: Reputational Suicide

In the age of social media and transparency, news of a plant shutdown due to negligence spreads fast. Investors lose confidence, stock prices can dip, and clients may look for “safer,” more reliable suppliers. A reputation built over 20 years can be dismantled in 20 minutes.

3. The Role of Specialized Safety Consulting

Preventing that one unsafe act requires a multi-layered defense system. You cannot rely on “common sense” alone. You need rigorous, specialized approaches to identify hazards before they manifest as behavior.

Addressing the Human Element

Since the majority of unsafe acts are behavioral, you must address the human psyche. You cannot engineer your way out of behavioral problems; you must train your way out. This is where a Behavior-Based Safety Consultant becomes invaluable.

Behavior-Based Safety (BBS) focuses on what people do, analyzes why they do it, and then applies an intervention strategy to improve what they do. A consultant in this field helps organizations move from a “policing” culture (punishing errors) to a “coaching” culture (correcting behavior positively). By observing workers and providing real-time feedback, a BBS program rewires the workforce’s approach to risk, ensuring that safety becomes a habit rather than a rule.

Addressing Process Hazards

Sometimes, an unsafe act triggers a disaster because the process itself was inherently risky. For example, a worker opens a valve too quickly. That is the unsafe act. But why did opening a valve lead to an explosion? Because the system wasn’t designed to handle the pressure surge.

To mitigate this, you need a HAZOP Consultant. A Hazard and Operability Study (HAZOP) is a systematic way to identify potential hazards and operability problems. The consultant guides your team through every pipeline, vessel, and node of your process, asking “What if?” questions. “What if flow stops?” “What if temperature rises?” By identifying these vulnerabilities, you can engineer safeguards that ensure a single unsafe act doesn’t lead to a catastrophic failure.

Addressing Infrastructure Risks

A common unsafe act is the blocking of fire exits or the improper storage of flammable materials. If a fire breaks out, these acts can turn a minor incident into a total loss of the facility. Regular intervention by a Fire Safety Audit Consultant ensures that your passive and active fire protection systems are functional. These audits check everything from the pressure in your fire extinguishers to the functionality of your sprinkler systems and the clearance of your evacuation routes. They ensure that if an unsafe act causes a spark, the plant survives the flame.

4. The Importance of Regular Auditing

The reality of industrial safety is that it degrades over time. Entropy applies to safety culture just as it applies to thermodynamics. Procedures get forgotten, shortcuts become normalized, and equipment ages.

To combat this “safety drift,” periodic third-party verification is essential. Conducting a comprehensive Safety Audit in India or your specific region allows for an objective “health check” of your facility.

Internal teams often develop “blind spots”—they walk past a hazard every day until they stop seeing it. An external auditor brings fresh eyes and deep expertise regarding local compliance laws (such as The Factories Act, 1948 in India) and international standards (ISO 45001). They don’t just look for violations; they look for the root causes of unsafe acts. They identify gaps in your management system that allow unsafe behaviors to fester.

5. Building a “Fail-Safe” Culture

Ultimately, the goal is to create an environment where an unsafe act is difficult to commit and, if committed, is caught before it causes harm. This requires a three-pronged approach:

1. Leadership Commitment

Safety starts at the top. If plant managers prioritize production speed over safety protocols, workers will pick up on that signal immediately. Management must be visible on the shop floor, wearing PPE, and following the rules.

2. Empowerment

Every employee, from the janitor to the chief engineer, must have the authority to stop work if they see an unsafe act. This “Stop Work Authority” is the most powerful tool in preventing shutdowns. If a worker sees a colleague about to enter a confined space without a permit, they should feel empowered to intervene without fear of retribution.

3. Continuous Education

One-time training is insufficient. Safety talks, toolbox talks, and refreshers must be constant. The message must be clear: We want you to go home to your family in the same condition you arrived.

Conclusion

The difference between a profitable year and a plant shutdown often hangs by a thread. That thread is the decision-making process of your workforce. One unsafe act—a moment of negligence, a shortcut, a lapse in judgment—can snap that thread, bringing your operations to a grinding, silent halt.

Don’t wait for the silence to fall over your factory. Be proactive. Whether it is through behavioral modification, rigorous process analysis, or comprehensive audits, the investment you make in safety today is the insurance policy for your business tomorrow.

At The Safety Master, we specialize in identifying the hidden risks that threaten your plant. From behavioral coaching to technical HAZOP studies, we provide the expertise to keep your people safe and your plant running.