Safeguarding Industrial Processes: The Basics of Safety Integrity Levels

The Hazop Study Process: Step-by-Step Approach with Examples

June 5, 2023

Building Fire Safety Risks: 5 Steps From Negligence to Management

June 5, 2023Safeguarding Industrial Processes: The Basics of Safety Integrity Levels

In this article, we’ll be discussing an issue that is critical to the safety and well-being of many industrial processes: Safety Integrity Levels (SIL). Many industries rely on complex systems that must operate flawlessly to prevent hazardous situations. Failing to properly safeguard these systems can lead to severe consequences for both employees and the environment. We’ll cover the basics of SIL, what it means, and why it’s essential to understand. By the end of this article, you’ll have a comprehensive understanding of how and why to implement SIL practices to safeguard your industrial processes. So, without further ado, let’s dive into the basics.

Introduction

Safeguarding industrial processes is vital, and it is important to ensure that they are safe and free from accidents. However, the reality is that industrial processes have inherent risks, and accidents can still happen despite the best efforts of all involved. In order to minimize these risks, safety measures must be put in place to create a safer work environment. One such safety measure is known as Safety Integrity Levels (SIL). This article will discuss the basics of SIL and how it can help safeguard industrial processes. We will explore the importance of SIL, how it is determined through risk assessment, and common mistakes to avoid when implementing this safety measure. By the end of this article, you will have a better understanding of SIL and its advantages in ensuring workplace safety

Understanding Safety Integrity Levels (SIL)

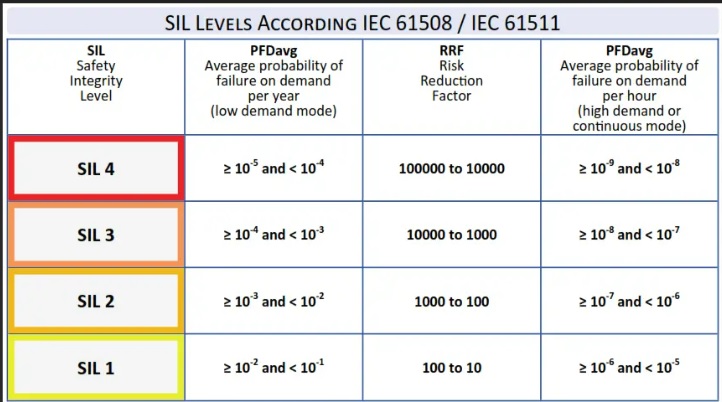

The understanding of Safety Integrity Levels (SIL) is crucial in safeguarding industrial processes. SIL refers to the degree of reliability that a safety system can provide in terms of risk reduction. In simpler words, it is a measure of the probability that a safety instrumented system (SIS) will perform its intended function when required.There are four levels of SIL, with SIL 1 being the lowest and SIL 4 being the highest. Each level represents an incremental increase in the degree of reliability required to ensure safety. SIL is determined based on the severity and frequency of hazards associated with equipment failure, as well as the probability of SIS failure.

Understanding SIL is critical for ensuring that any industrial process has adequate safeguards in place to protect people, equipment, and the environment. It enables organizations to make informed decisions about selecting appropriate SISs for their operations and helps them develop risk management strategies that prioritize safety and prevent accidents from occurring. Therefore, it’s essential to seek guidance from experienced professionals who understand how SIL works and how it can be applied effectively in various industrial settings.

Importance of SIL in Ensuring Safety in Industrial Processes

In the industrial world, safety is of utmost importance. The lives of workers and the integrity of machines are at risk when safety is disregarded. This is where Safety Integrity Levels (SIL) come in to play. SIL is a measure of reliability that ensures safety in industrial processes.SIL identifies the level of risk associated with a particular process or equipment and provides a benchmark for ensuring that the necessary safeguards are in place to mitigate that risk. By implementing SIL, companies can be assured that their processes are operating within an acceptable level of risk and that appropriate measures have been taken to prevent accidents or malfunctions from occurring.

The importance of SIL cannot be overemphasized as it ensures the safety of workers and equipment, protects company reputation, and saves resources by preventing accidents or breakdowns. Companies must prioritize SIL as part of their overall approach to safety management if they want to maintain high levels of productivity while keeping their workforce safe.

The Role of Risk Assessment in Determining SIL

The Role of Risk Assessment in Determining SIL:One of the critical factors in determining Safety Integrity Levels (SIL) is conducting a thorough risk assessment. A risk assessment involves identifying potential hazards, assessing the likelihood of their occurrence, and evaluating the consequences if they were to occur. This process informs the selection of appropriate SIL levels for different safety functions.

During a risk assessment, it’s important to consider all possible scenarios that could lead to hazardous situations. For example, an industrial process involving flammable materials may require SIL 3 or higher if a leak or explosion could have catastrophic effects. In contrast, a less critical process may only require lower SIL levels.

By conducting a comprehensive risk assessment, organizations can ensure that safety systems are designed to provide adequate protection for workers and the environment. It also helps prevent costly downtime due to accidents or equipment failures while promoting operational efficiency and regulatory compliance.

Overall, risk assessments play an essential role in determining appropriate Safety Integrity Levels for industrial processes. By using this approach, organizations can mitigate risks effectively and prevent potential hazards from occurring while providing optimal protection for workers and equipment.

Benefits and Challenges of Implementing SIL

One of the benefits of implementing SIL in industrial processes is increased safety. SIL provides a systematic approach to identifying, assessing, and mitigating risks associated with process operations. This leads to a reduction in the likelihood of accidents or incidents occurring, which in turn minimizes the potential for injury or loss of life.Another benefit is improved productivity. The implementation of SIL can result in increased operational efficiency through the identification and elimination of unnecessary steps that may compromise safety. This can result in better process control and greater plant availability, which ultimately leads to improved product quality and increased profitability.

However, implementing SIL also presents some challenges. One such challenge may be resistance from employees who may perceive it as an additional burden on their daily activities. Additionally, implementing effective safety measures requires skilled personnel who understand the principles behind SIL implementation and risk assessment techniques.

Overall, while there are challenges associated with implementing SIL, the benefits are numerous and include safer work environments, improved productivity, better product quality, and increased profits for organizations that adopt these principles effectively.

Common Mistakes to Avoid in Implementing SIL

One common mistake in implementing SIL is the assumption that all safety devices are equal. Each device must meet specific standards for performance and reliability, and failure to recognize these differences can lead to insufficient protection. It’s important to do thorough research on the devices being used and ensure they meet the necessary requirements.Another mistake is failing to properly train personnel on SIL implementation and maintenance procedures. Lack of training can lead to improper installation or maintenance of safety devices, which can compromise their effectiveness. Companies should invest in ongoing education and training programs for employees involved in SIL implementation.

A third mistake is overlooking the need for regular testing and maintenance of safety devices. Even if devices are installed correctly, they can fail over time due to wear and tear or environmental factors. Regular testing and maintenance helps ensure that all safety devices are functioning as intended, providing optimal protection for industrial processes.

Conclusion

As we have explored in this article, Safety Integrity Levels (SIL) play a critical role in ensuring safety in industrial processes. By identifying and managing risks, implementing SIL can help prevent accidents, protect workers, and minimize the potential loss of equipment or product. While there are benefits to implementing SIL, such as improved safety and reduced downtime due to accidents and incidents, there are also challenges such as complexity of implementation. However, with proper planning and execution, the benefits of implementing SIL far outweigh the challenges.

At TSM TheSafetyMaster Private Limited we offer following services

TSM TheSafetyMaster® Private Limited

DUST EXPLOSION HAZARD ASSESSMENT

ELECTROSTATIC HAZARD ASSESSMENT

Unit No 221-451-452, SPL1/J, 2nd & 4th Floor, Sunsquare Plaza Complex, RIICO Chowk, Bhiwadi 301019, Rajasthan, India

Phone: +91 1493 22 0093

Mobile: +91 7665231743/9413882016

Email: info@thesafetymaster.com