The Importance of Arc Flash Studies in Industrial Settings

Demystifying Fire Explosions: A Comprehensive Look at Flammable Gases and Their Properties

June 2, 2023

The Hazop Study Process: Step-by-Step Approach with Examples

June 5, 2023The Importance of Arc Flash Studies in Industrial Settings

In this article, we will explore a critical issue that demands attention within industrial settings: arc flash studies. We will examine the dangers and consequences of failing to conduct these studies, discuss the crucial role they play in promoting worker safety, and offer practical guidance for implementing them effectively. By the end of this article, readers will have a clear understanding of the importance of arc flash studies and how they can protect their employees, facilities, and bottom line. So, let’s delve into this crucial topic and discover the power of prevention.

Introduction

Industrial settings are home to powerful equipment, electrical systems and high voltage circuits. Every year, accidents in these settings cause catastrophic damage to both human lives and property. One of the major threats that industrial workers face is Arc Flash. It is an electrical discharge that happens when an electric current jumps from one conductor to another through the air.Arc Flash can cause severe burns, blindness or even death in a matter of seconds. The thermal energy released during Arc Flash is equivalent to a small bomb explosion, which can have devastating consequences for anyone within its vicinity. This article will explore the importance of Arc Flash Studies in Industrial Settings and how they can help prevent accidents and save lives

What is an Arc Flash?

An arc flash is a dangerous electrical event that can occur when there is a sudden release of energy due to a fault in the electrical system. It happens when an electric arc passes through the air between two conductors, creating plasma that heats up to thousands of degrees Celsius. The intense heat generated by an arc flash can cause explosions, fires, and serious injuries or fatalities. Arc flashes are unpredictable and can happen in seconds without warning. They can be caused by many different factors such as equipment failure, human error, or environmental conditions. Arc flashes are not only dangerous but also costly; they can cause damage to expensive equipment and disrupt business operations.

It is critical for companies to understand the risks associated with arc flashes and take measures to prevent them from happening. An effective way to do this is through conducting regular arc flash studies to identify potential hazards and implement appropriate safety measures. By understanding what causes an arc flash and how it behaves, companies can take steps to mitigate the risks associated with this dangerous electrical event.

The Dangers of Arc Flash

Arc flash is one of the most dangerous and devastating electrical hazards that can occur in an industrial setting. It is a sudden release of energy caused by an electrical arc, which can produce temperatures as high as 35,000 degrees Fahrenheit. This extreme heat can cause severe burns to anyone within its proximity and ignite any flammable materials in the area.Apart from severe burns, arc flash can cause other serious injuries like hearing loss and vision impairment due to the intense light and sound produced during the event. The pressure wave generated by an arc flash can also throw people across the room or knock them off their feet. In addition to this, the explosion caused by arc flash can damage equipment, resulting in costly repairs or replacement.

It’s important for employers to understand these dangers and take necessary precautions to prevent arc flashes from occurring. By conducting thorough arc flash studies, employers can identify potential hazards in their facility and implement measures to reduce risk and protect their employees’ safety.

Importance of Arc Flash Studies

An arc flash is an electrical phenomenon that occurs when a high voltage electric current jumps the gap between two conductors. This causes an explosion-like event that releases vast amounts of energy in the form of heat, light, and sound. The dangers of arc flash cannot be overstated, as they can cause severe burns, permanent injuries, and even death. This is where the importance of arc flash studies comes into play. Arc flash studies are a critical part of any industrial setting that deals with high-voltage electricity. These studies help identify potential hazards and provide recommendations for how to mitigate them.

Arc flash studies involve a comprehensive analysis of the electrical system in question. They take into account factors such as voltage levels, equipment design and conditions, fault current levels, and more. With this information in hand, engineers can accurately predict the likelihood and severity of arc flash incidents occurring on site.

Implementing the findings from arc flash studies can lead to significant improvements in safety for workers on site. This includes making changes to equipment design or placement, implementing better personal protective equipment (PPE), providing adequate training for employees on safety protocols during maintenance tasks or emergencies involving electricity etc., all resulting in minimizing accidents due to arc flashes which ultimately leads to reduction in costs associated with medical care and lost productivity due to employee injury or death.

Components of Arc Flash Studies

Components of Arc Flash Studies: An Arc Flash study is a critical risk assessment tool that aids in identifying potential hazards in an industrial setting. The study typically includes a comprehensive analysis of all electrical equipment and systems, as well as the environment and work procedures. The study should be carried out by qualified professionals who have extensive knowledge in electrical engineering, safety standards, and regulations.

The components of an arc flash study include a review of the facility’s one-line diagram, which identifies the location and rating of all electrical equipment. Detailed measurements are taken to determine the short-circuit current available at each piece of equipment. The arc flash boundary is then calculated based on this information, which determines the safe working distance from exposed energized parts.

Other key components include performing a protective device coordination analysis to ensure that protective devices operate correctly during fault conditions. A fault current analysis will also be completed to ensure that all breakers are sized appropriately for anticipated faults within the system. These components are crucial in determining optimal safety measures in an industrial setting to minimize risks associated with arc flash incidents.

Benefits of Arc Flash Studies

Benefits of Arc Flash Studies

Arc flash studies provide numerous benefits to industrial facilities. Firstly, they help in identifying potential hazards and risks that are associated with electrical equipment. Once these risks and hazards are identified, appropriate safety measures can be put in place to mitigate them, thereby reducing the likelihood of accidents and injuries.Secondly, arc flash studies also help in optimizing the performance of electrical equipment by identifying areas for improvement or where upgrades may be necessary. This leads to increased efficiency and productivity while reducing costs associated with maintenance and repairs.

Lastly, conducting arc flash studies can improve overall compliance with safety regulations and standards set by regulatory bodies such as OSHA. This not only enhances the safety of employees but also helps organizations avoid costly penalties associated with non-compliance.

In conclusion, implementing an effective arc flash study program can result in significant benefits for industrial facilities. By identifying potential hazards and risks associated with electrical equipment, optimizing performance, and enhancing compliance with safety regulations, organizations can ensure the safety of their employees while achieving optimal efficiency at reduced costs.

Implementation of Arc Flash Study Results

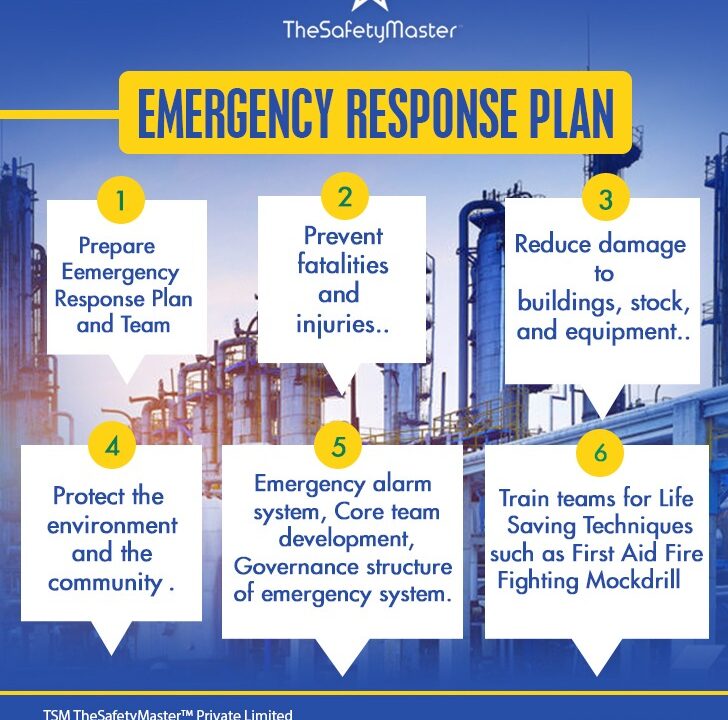

After conducting an arc flash study, it is crucial to implement the results in order to reduce the risk of arc flash incidents. This involves following the recommendations provided in the study, such as updating electrical equipment and implementing safety procedures.One of the key components of implementing arc flash study results is establishing a maintenance program. This includes regularly inspecting and testing electrical equipment to ensure it is functioning safely and effectively. Additionally, it may involve replacing outdated or faulty equipment with newer, safer alternatives.

Employee training is also essential for implementing arc flash study results. Employees must be educated on proper safety procedures and how to work around electrical equipment safely. Regular training sessions can help reinforce these practices and ensure that employees are aware of any updates or changes made as a result of the arc flash study.

Overall, implementing arc flash study results requires a comprehensive approach that involves updating equipment, establishing maintenance programs, and providing employee training. By taking these steps, companies can significantly reduce the risk of arc flash incidents and create a safer work environment for everyone involved.

Employee Training and Arc Flash Safety

Employees are the backbone of any organization and ensuring their safety is a top priority. When it comes to arc flash incidents, employees need to be educated and trained on how to handle them in an effective manner. This not only protects themselves but also their colleagues and the equipment they are working with.Training programs should cover various aspects, such as basic electrical safety, hazard identification, personal protective equipment (PPE) selection, and emergency response procedures. Employees should also be taught how to read arc flash labels and interpret incident energy levels so that they can take necessary precautions accordingly.

Effective training can greatly reduce the risk of arc flash incidents in industrial settings. It empowers employees with knowledge and skills to work safely around electrical equipment. Thus, providing regular training sessions for all workers is crucial for creating a culture of safety in any industrial workplace.

Conclusion

In conclusion, implementing arc flash studies in industrial settings is crucial for ensuring the safety of employees and minimizing the risk of devastating accidents. By identifying potential hazards and implementing proper safety measures, employers can create a safer work environment for everyone. Although arc flashes can be extremely dangerous, they can be prevented with the proper tools and knowledge. Let us continue to prioritize safety in industrial settings with the use of arc flash studies to protect both employees and businesses alike.

At TSM TheSafetyMaster Private Limited we offer following services

TSM TheSafetyMaster® Private Limited

Unit No 221-451-452, SPL1/J, 2nd & 4th Floor, Sunsquare Plaza Complex, RIICO Chowk, Bhiwadi 301019, Rajasthan, India

Phone: +91 1493 22 0093

Mobile: +91 7665231743/9413882016

Email: info@thesafetymaster.com