Building a Safety Culture in Punjab Manufacturing Sites: A 12-Month Roadmap

HIRA & Risk Assessment Best Practices for Punjab-Based Food-Processing Plants

November 10, 2025

Fire Safety & Emergency Preparedness for Factories in Punjab: What You Must Know

November 11, 2025Creating a strong safety culture in manufacturing isn’t just about compliance—it’s about shaping behaviors, systems, and values that keep every worker safe, every day. In Punjab, where industrial hubs like Ludhiana, Mohali, and Bathinda drive India’s manufacturing output, the need for a structured approach to safety is more critical than ever. The following 12-month roadmap is designed to help organizations embed safety deeply into their operations using proven principles aligned with global standards and The Safety Master’s expertise.

Why Safety Culture Matters

A genuine safety culture ensures that every employee, from the shop floor to the boardroom, treats safety as an integral part of their job. It’s not just about avoiding fines or accidents—it’s about trust, efficiency, and reputation. Companies with strong safety cultures often report higher productivity, lower downtime, and better employee morale. In Punjab’s growing industrial ecosystem, this can be the difference between being compliant and being competitive.

Month 1–2: Assess and Establish the Baseline

Before improving safety, you must first understand where you stand. Begin with a comprehensive Safety Audit to evaluate current policies, infrastructure, and compliance with national standards such as the Factories Act, 1948 and ISO 45001.

Key Steps:

- Identify gaps in existing safety management systems.

- Evaluate machinery safety, PPE compliance, and emergency preparedness.

- Interview key personnel to understand current safety attitudes.

Deliverables:

- Safety baseline report

- Compliance checklist

- Initial training needs analysis

This baseline helps leaders set realistic goals and prioritize high-risk areas before rolling out new initiatives.

Month 3–4: Build Leadership Commitment

Safety culture starts at the top. Senior management must visibly demonstrate their commitment through regular communication, participation in safety programs, and resource allocation.

Actions for Leadership:

- Appoint a safety champion or internal EHS head.

- Integrate safety metrics into performance reviews.

- Conduct workshops to align leadership goals with safety outcomes.

Leadership visibility is crucial—employees emulate what they see. When top management walks the talk, safety moves from being a rule to being a shared responsibility.

Month 5–6: Identify and Control Risks

Once the groundwork is set, the next phase involves proactive risk identification and mitigation. Conducting a Hazop Study (Hazard and Operability Study) is essential for manufacturing units dealing with chemicals, fuels, or complex mechanical systems.

Focus Areas:

- Process design safety and hazard identification

- Operational deviations and their potential consequences

- Recommendations for engineering and procedural controls

By the end of this phase, the site should have an actionable risk register, clear mitigation strategies, and assigned responsibilities for every hazard identified.

Month 7: Train, Communicate, and Engage

Even the best safety systems fail without awareness and participation. Develop a structured training calendar targeting different employee levels—from operators to plant managers.

Training Topics:

- Fire and electrical safety

- Safe machine operation and lockout/tagout procedures

- Behavioral safety and hazard reporting

Encourage open dialogue about safety. Introduce “Safety Suggestion Boxes,” recognition programs for safe behavior, and weekly toolbox talks. Communication fosters ownership—when workers feel heard, they become active participants in maintaining safety.

Month 8: Strengthen Fire Safety Preparedness

Fire incidents remain one of the most common industrial hazards. Conduct a comprehensive Fire Audit to evaluate detection systems, evacuation plans, and response readiness.

Checklist for Fire Preparedness:

- Verify compliance with NBC and local fire authority norms.

- Assess placement and maintenance of fire extinguishers, sprinklers, and alarms.

- Conduct mock drills to test emergency response times.

Fire safety isn’t just about equipment—it’s about coordination. Every employee must know their role in an emergency.

Month 9–10: Implement Process Safety Management

As operations mature, it’s time to institutionalize systems that ensure consistency. Process Safety Management (PSM) provides a structured framework to prevent accidents, particularly in chemical and energy-intensive industries.

Core Elements to Establish:

- Process hazard analysis (PHA)

- Mechanical integrity and preventive maintenance

- Management of change (MOC) procedures

- Incident investigation and corrective actions

PSM implementation ensures that risk control is continuous—not a one-time effort. It ties safety directly into operational efficiency.

Month 11: Review, Audit, and Refine

At this stage, revisit your progress. Conduct an internal or third-party safety review to validate improvements. Compare current data—incident rates, near misses, and training completion—against the baseline established in Month 2.

Evaluation Criteria:

- Are safety KPIs improving?

- Are employees following standard operating procedures (SOPs)?

- Are corrective actions from earlier audits implemented effectively?

Continuous improvement is the heart of a lasting safety culture. Learn from what worked and what didn’t, and use that insight to refine your systems.

Month 12: Celebrate, Sustain, and Scale

The final month is about embedding safety as a permanent part of your organizational DNA. Celebrate milestones, reward departments or teams for exemplary safety performance, and document best practices for future reference.

Actions to Sustain Progress:

- Publish monthly safety newsletters.

- Conduct refresher trainings and annual reviews.

- Integrate safety KPIs into annual strategic planning.

Recognition reinforces positive behavior, while consistent measurement ensures that the safety culture continues to evolve long after the 12-month roadmap ends.

Challenges in Building a Safety Culture in Punjab

While Punjab’s manufacturing strength is undeniable, several factors make safety culture adoption challenging:

- Informal workforces often lack formal safety training.

- Legacy machinery without modern safety interlocks.

- Limited EHS budgets for small and medium industries.

- Low awareness about advanced audits and risk assessment techniques.

Overcoming these requires collaboration among industry leaders, safety consultants, and government agencies. Regional associations and safety partners like The Safety Master play a vital role in bridging this gap by offering training, audits, and continuous guidance.

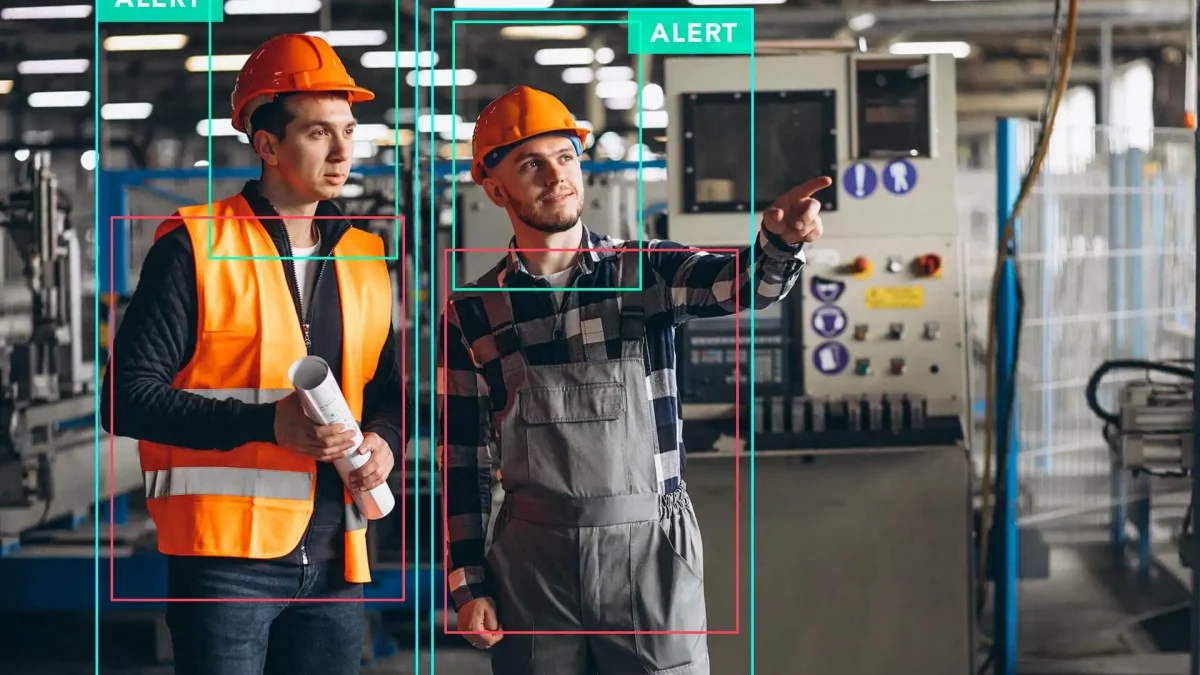

The Role of Technology in Modern Safety Systems

Digital transformation is redefining safety management. Smart sensors, AI-based risk prediction, and cloud-based reporting platforms are helping industries shift from reactive to predictive safety models.

Technologies to Integrate:

- IoT-based fire and gas detection systems.

- Mobile apps for incident reporting and compliance tracking.

- Data analytics for identifying unsafe trends.

Leveraging these tools ensures real-time visibility and faster corrective actions, crucial for large manufacturing clusters spread across Punjab.

Measuring the Success of Your Safety Culture

Success isn’t just about fewer accidents—it’s about measurable behavioral and organizational changes.

Key Indicators Include:

- Reduction in lost time injuries (LTIs)

- Increased reporting of near misses (a sign of awareness)

- 100% training completion across all departments

- Regular audit compliance without external triggers

When safety becomes self-sustaining—driven not by enforcement but by conviction—you’ve built a real safety culture.

Final Thoughts

Building a safety culture isn’t a sprint; it’s a sustained journey. For Punjab’s manufacturing sector, the next decade offers immense growth—but only those organizations that prioritize people’s safety will truly thrive. This 12-month roadmap provides a structured pathway, blending leadership commitment, employee engagement, risk assessment, and system integration.

The Safety Master’s specialized services—from Hazop Study and Safety Audit to Fire Audit and Process Safety Management—offer the technical depth and expertise industries need to achieve sustainable safety excellence.

By following this roadmap, Punjab’s manufacturing units can not only meet compliance requirements but also create workplaces where every individual feels valued, protected, and empowered to contribute to a safer, more productive industrial ecosystem.