Embracing Excellence in Process Safety Management with Expert Handholding

Safety Gap Assessment with Technology and Artificial Intelligence

April 9, 2024

Bridging Safety Gaps with Technology and AI

April 19, 2024In the complex world of industrial operations, safety transcends basic compliance; it embodies the heart of operational excellence. Process Safety Management (PSM) stands as a critical pillar in this realm, aiming to prevent severe accidents involving the release of hazardous chemicals. This approach is not just regulatory—it’s a moral imperative and a business necessity. In this context, the role of expert handholding, especially from a seasoned Safety Master, becomes invaluable in navigating the intricate landscape of PSM.

The Significance of Process Safety Management

PSM is more than a set of compliance requirements; it’s a comprehensive management system designed to ensure facilities handle hazardous chemicals safely. The genesis of PSM can be traced back to tragic incidents that highlighted the devastating consequences of inadequate chemical process safety. Regulatory bodies like the Occupational Safety and Health Administration (OSHA) have since instituted stringent standards, but true safety goes beyond mere compliance. It requires a holistic approach that integrates safety into every facet of operation, from design to decommissioning.

Core Elements of Effective PSM

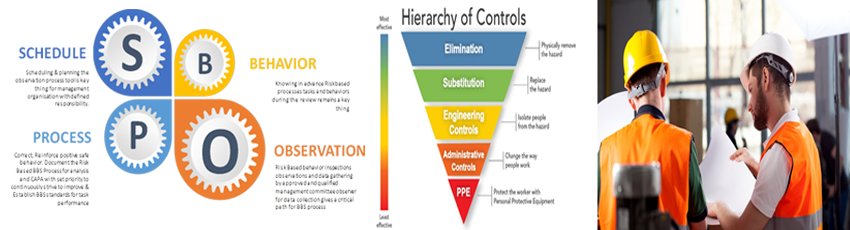

A robust PSM program is built on several foundational pillars:

- Process Safety Information (PSI): Comprehensive documentation of all hazardous substances and technology used in processes.

- Process Hazard Analysis (PHA): Systematic analysis to identify potential hazards associated with chemical processes.

- Operating Procedures: Clear and concise guidelines for safely conducting and maintaining operations.

- Training: Ensuring that employees are knowledgeable and competent in the operations they manage.

- Mechanical Integrity: Regular inspections and maintenance of equipment to ensure it is safe and operable.

- Management of Change: A formal system for managing changes that could affect the safety of a process.

- Incident Investigation: Rigorous approach to learning from past incidents to prevent future occurrences.

These elements, when effectively managed, create a safety ecosystem that guards against complacency and fosters a culture of continuous improvement.

The Role of The Safety Master in PSM

Implementing an effective PSM system is no small feat—it requires expertise, persistence, and a deep understanding of both technical and organizational aspects. This is where The Safety Master steps in. Acting as a guiding force, The Safety Master provides specialized knowledge and experience to help organizations navigate the complexities of process safety.

The Safety Master’s role can be pivotal in several ways:

- Expert Guidance: From setting up PSI databases to conducting PHAs, The Safety Master ensures that all technical and regulatory aspects are addressed comprehensively.

- Customized Training: Tailoring training programs to meet the specific needs of the organization, ensuring that all levels of personnel understand their roles in maintaining safety.

- Cultural Transformation: Helping foster a safety culture where every employee feels responsible for process safety, thus embedding safety as a core organizational value.

- Continuous Improvement: Offering ongoing support to review and enhance PSM activities, ensuring they evolve with technological advancements and regulatory changes.

Overcoming Challenges with Expert Handholding

Many organizations face significant hurdles in implementing an effective PSM system, such as resource limitations, lack of specialized knowledge, and resistance to change. The Safety Master provides the much-needed support to overcome these challenges by:

- Providing Resources: Augmenting the organization’s capabilities with additional expert resources and specialized tools.

- Bridging Knowledge Gaps: Offering deep insights and up-to-date knowledge of industry best practices and regulatory requirements.

- Driving Organizational Change: Assisting in change management to ensure that safety becomes an integral part of the operational mindset.

Success Stories

The impact of The Safety Master’s handholding is evident in numerous success stories across industries. For instance, a chemical manufacturing plant struggling with recurring safety incidents saw a dramatic turnaround after adopting the expert-recommended PSM framework. Through rigorous PHAs, revamped training programs, and a revamped safety culture, the plant not only reduced its incident rate but also enhanced its operational efficiency.

Conclusion

The journey towards exemplary process safety is ongoing and dynamic. With regulations becoming stricter and operational environments more complex, the need for expert handholding in PSM has never been greater. The Safety Master plays a crucial role in this journey, ensuring that safety is not just a compliance requirement but a cornerstone of operational excellence. For organizations looking to excel in safety management, partnering with a Safety Master is not just an option—it’s a strategic imperative.